Features

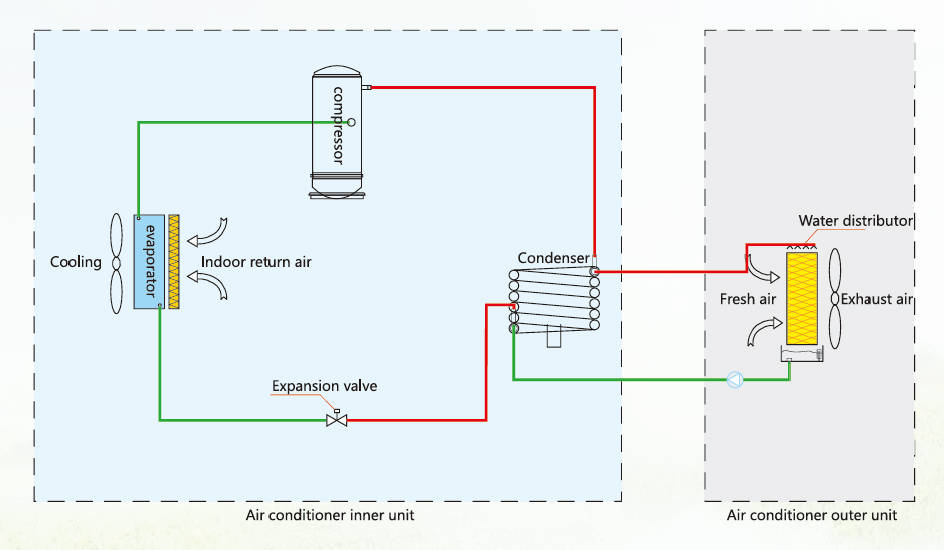

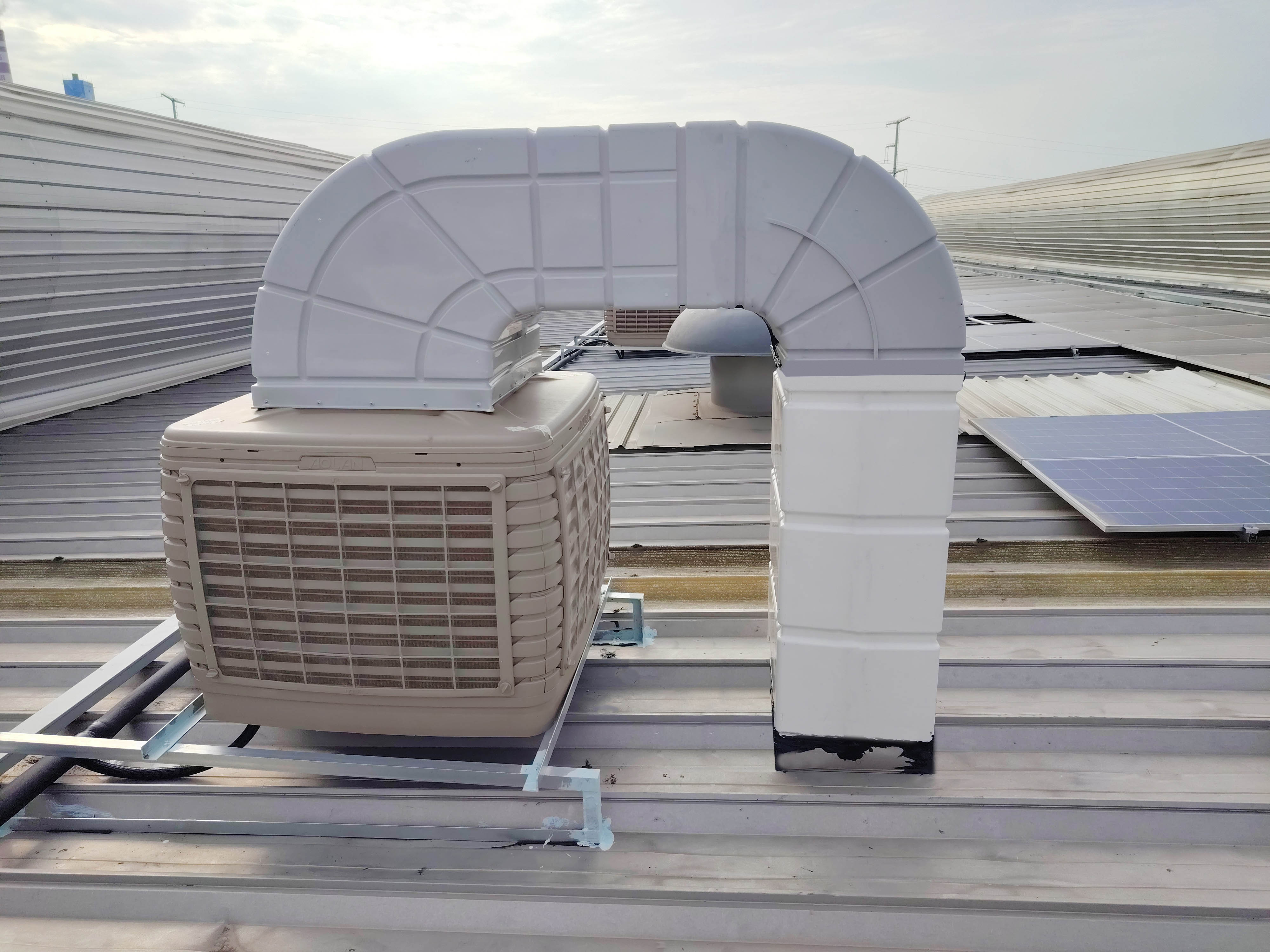

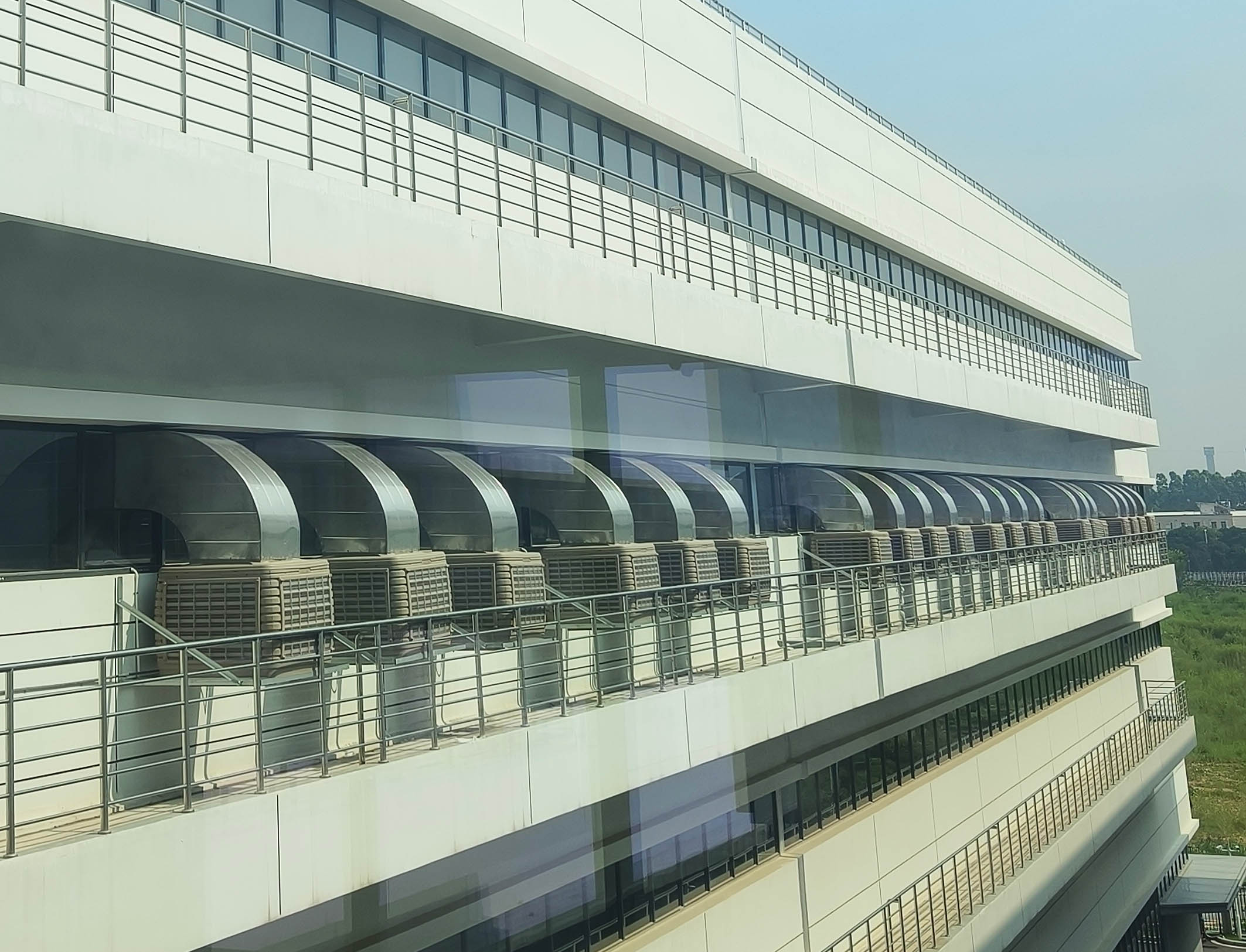

1.High Efficiency and Energy Saving: Compared to traditional air conditioners, the eco-friendly and energy-saving air conditioner reduces energy consumption by 30–50%.

2.Easy Installation and Maintenance: Only PVC water pipes are required to connect indoor and outdoor units. No copper pipes needed, making installation and upkeep simple.

3.Smart Control: Supports manual, remote control, and remote app control functions, enabling remote management and operation.

4.Economical and Eco-Friendly: Incorporates condensate water recycling technology, improving product performance while reducing water waste.

Application

The eco-friendly and energy-saving air conditioner is suitable for various industrial and commercial settings, including factory workshops, warehouses, logistics centers, pharmaceutical manufacturing facilities, etc.

Specification

Model | Coolong Capacity (kW) | Power (kW) | Electrical Source (V/Hz) | Airflow (m³/h) | Water Flow (m³/h) | Weight (kg) | Dimensions (L*W*H)(mm) |

AHK25-ZLA | 25 | 4.5 | 380V-50Hz | 6000 | 4 | (IDU)150 (ODU)120 | (IDU)800*550*1860 (ODU)800*800*1350 |

AHK35-ZLA | 35 | 6.4 | 380V-50Hz | 7000 | 5 | (IDU)180 (ODU)122 | (IDU)800*550*1860 (ODU)800*800*1350 |

Note:

1.For detailed models and specifications, please consult our sales representatives.

2.Product specifications are subject to change without prior notice due to ongoing improvements. Please refer to the actual parameters of the equipment.

Features

1.High Efficiency and Energy Saving: Compared to traditional air conditioners, the eco-friendly and energy-saving air conditioner reduces energy consumption by 30–50%.

2.Easy Installation and Maintenance: Only PVC water pipes are required to connect indoor and outdoor units. No copper pipes needed, making installation and upkeep simple.

3.Smart Control: Supports manual, remote control, and remote app control functions, enabling remote management and operation.

4.Economical and Eco-Friendly: Incorporates condensate water recycling technology, improving product performance while reducing water waste.

Application

The eco-friendly and energy-saving air conditioner is suitable for various industrial and commercial settings, including factory workshops, warehouses, logistics centers, pharmaceutical manufacturing facilities, etc.

Specification

Model | Coolong Capacity (kW) | Power (kW) | Electrical Source (V/Hz) | Airflow (m³/h) | Water Flow (m³/h) | Weight (kg) | Dimensions (L*W*H)(mm) |

AHK25-LDA-S | 25 | 5.1 | 380V-50Hz | 6000 | 4 | (IDU)165 (ODU)120 | (IDU)1400*850*750 (ODU)800*800*1350 |

AHK35-LDA-S | 35 | 6.7 | 380V-50Hz | 7000 | 5 | (IDU)210 (ODU)122 | (IDU)1400*850*750 (ODU)800*800*1350 |

Note:

1.For detailed models and specifications, please consult our sales representatives.

2.Product specifications are subject to change without prior notice due to ongoing improvements. Please refer to the actual parameters of the equipment.

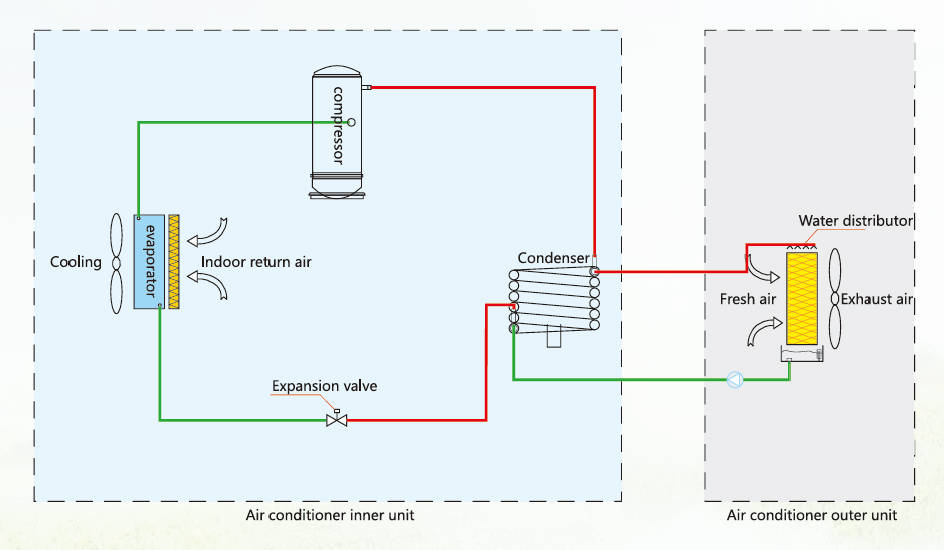

Overview

Aolan HVLS series large ceiling fans adopts efficient and reliable permanent magnet external rotor power design, high-strength aviation aluminum-magnesium alloy blades, and Aolan's unique high temperature resistant tail, which can effectively protect large space environments (workshops, shopping malls, halls, cattle raising Field, etc.) to organize the indoor airflow, improve the ventilation effect, and enhance the comfort of the human body. Large air volume, low rotation speed, the effective coverage space of the 7.3m large ceiling fan reaches more than 1700 square meters (wind speed>1.0m/s). In summer, cooperate with Aolan evaporative air cooler to cool down the area. Through Aolan's self-developed intelligent control system, it can achieve the greatest energy saving effect. It is suitable for installation on the ceiling of cement beam, I-beam and square steel structure.

Features

1. The permanent magnet synchronous motor PMSM used is a substitute for the traditional asynchronous motor + reducer, which is energy-saving and has a low failure rate;

2. The electronic control system has strong compatibility. System group control can be realized according to customer application requirements, and remote monitoring can be carried out through the Internet of Things to realize intelligent operation;

3. Unique safety design: ◆With fault indicator light, ◆With emergency stop button, ◆Electronic control box with tagging and locking function to avoid operation by unrelated personnel.

Safety Performance

Aolan industrial large ceiling fans can meet the safety requirements that the large ceiling fan parts will not fall under the following extreme accidents:

1. The motor shaft fails;

2. The motor bearing is broken and failed;

3. Accidental collision.

Aolan has also optimized the safety performance in the following areas, making it more user-friendly:

● Fault indicator light of large ceiling fan pole and control box;

● Emergency stop button in control box;

● The electric control box with tag-locking function avoids operation by unrelated personnel;

● IP55 motor and control box protection.

Application

Large logistics warehouses and distribution centers: Improve air quality, dehumidify and cool down, and improve working environment.

Large workshops: workshops such as machining and automobile manufacturing can improve ventilation efficiency.

Public buildings: such as shopping malls, auditoriums, airport stations and other places with large crowds, promote air circulation, disperse odors, and create a comfortable public environment.

Large-scale farms: including cattle farms, feedlots, hatcheries, etc. Improve air quality, dehumidify, remove odors, and reduce livestock morbidity.

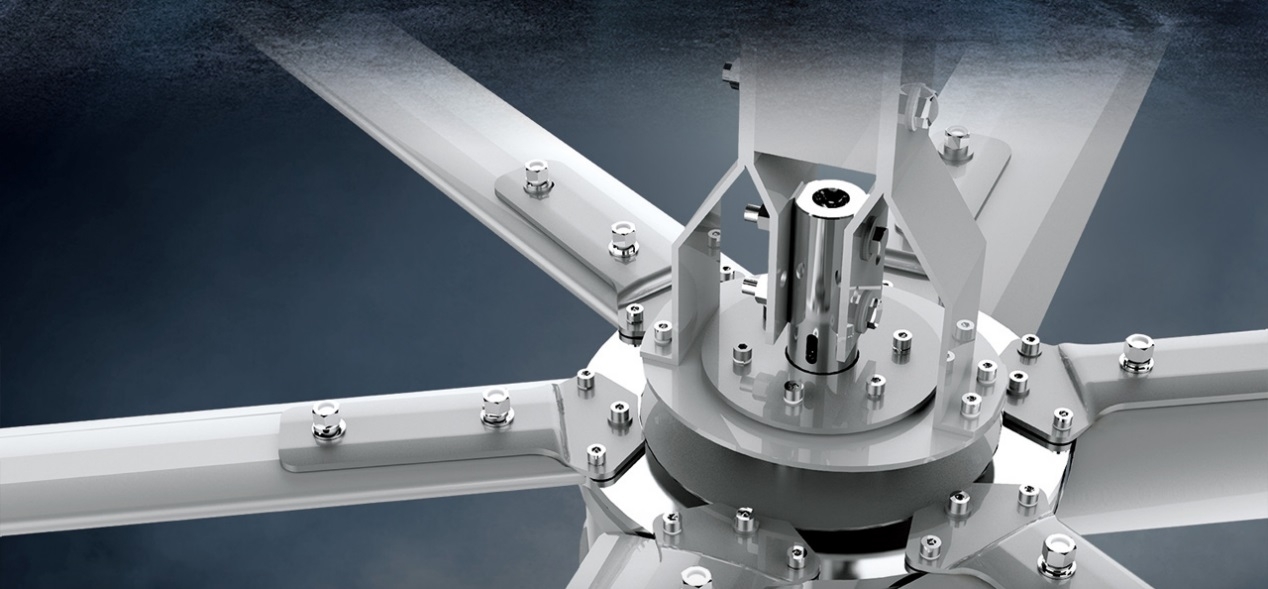

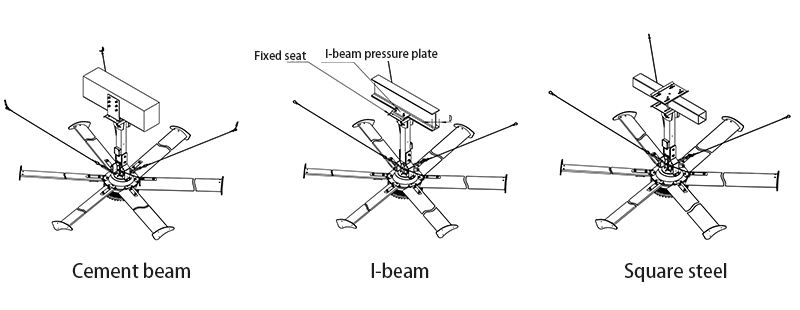

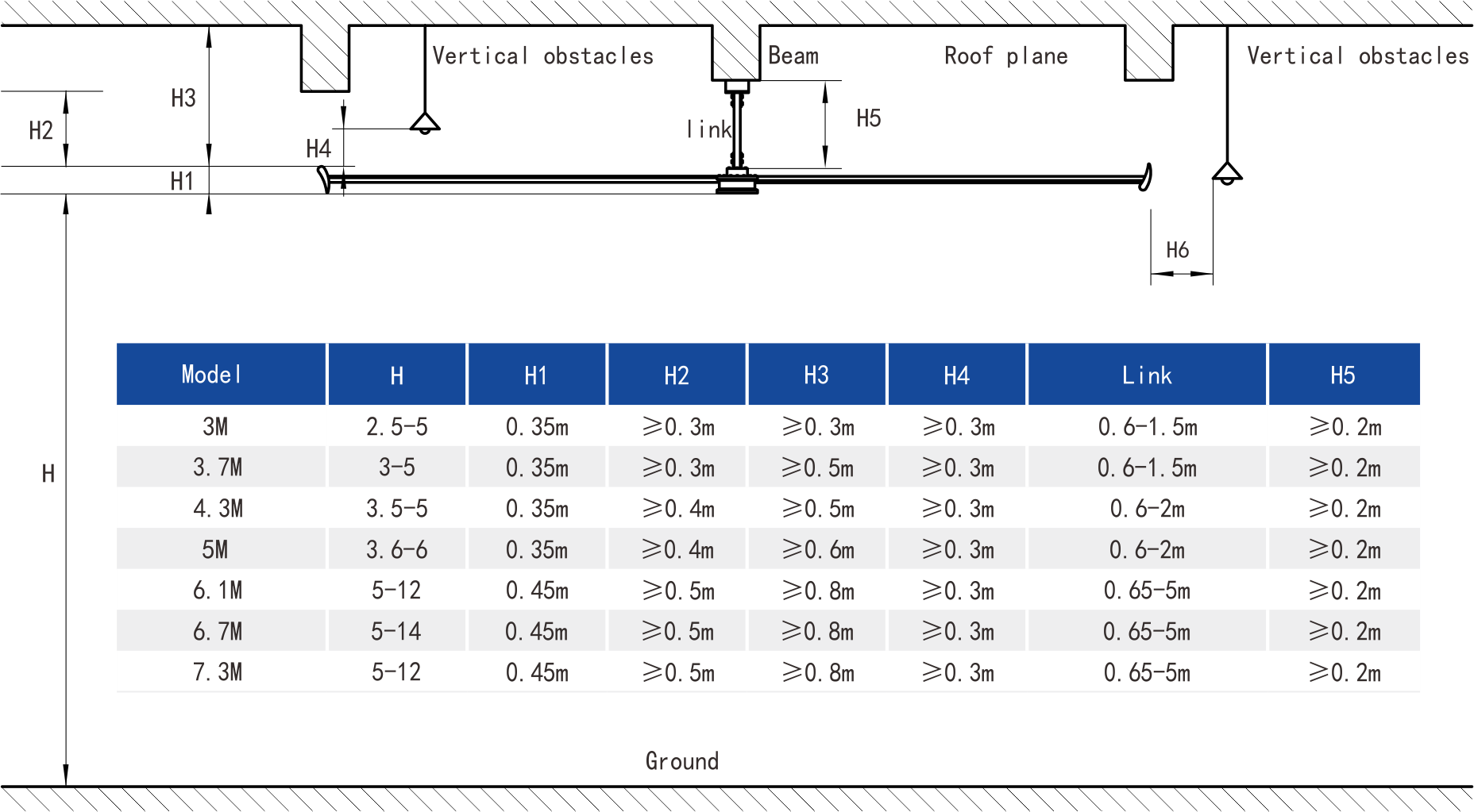

Installation Method

Specification

| Model | AL-HVLS-380-7300 | AL-HVLS-380-5000 |

| Blade Diameter (mm) | 7.3 | 5.0 |

| Blade Number (pcs) | 6 | 5 |

| Input Voltage (V) | 110/220/380 | 110/220/380 |

| Rotating Speed (r/min) | 15-55 | 20-80 |

| Max Airflow (m³/h) | 15500 | 10000 |

| Full Load Power (kW) | 1.5 | 0.75 |

| Covered Arer (m²) | 1700 | 750 |

| Max Noise (dB(A)) | 38 | 38 |

| Total Weight (kg) | 122 | 49 |

For other fan blade diameter requirements, please contact Aolan sales engineer.

Installation Space Requirements

Project Cases

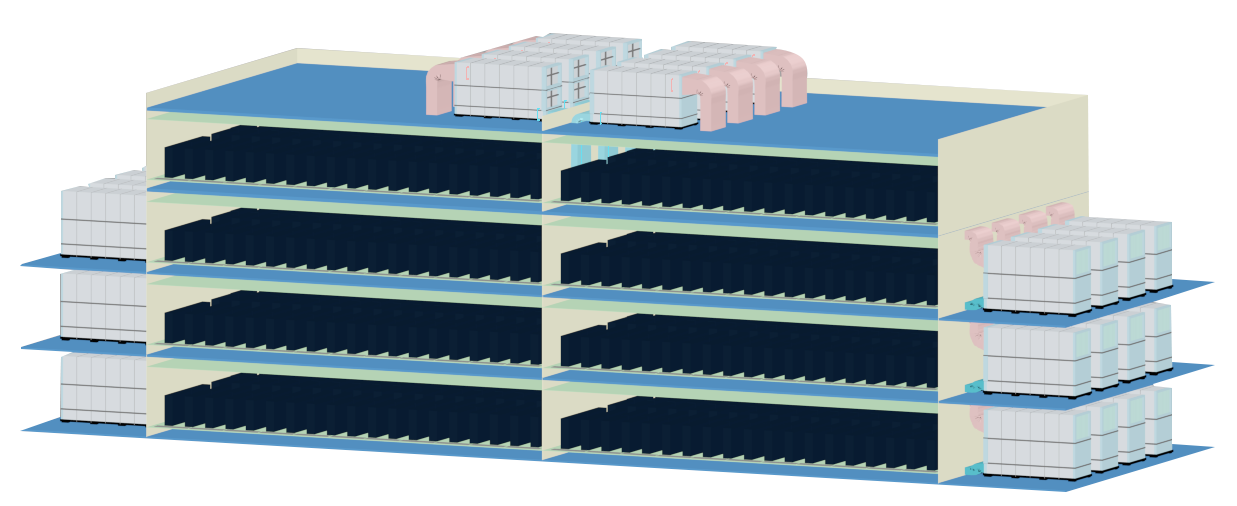

Overview

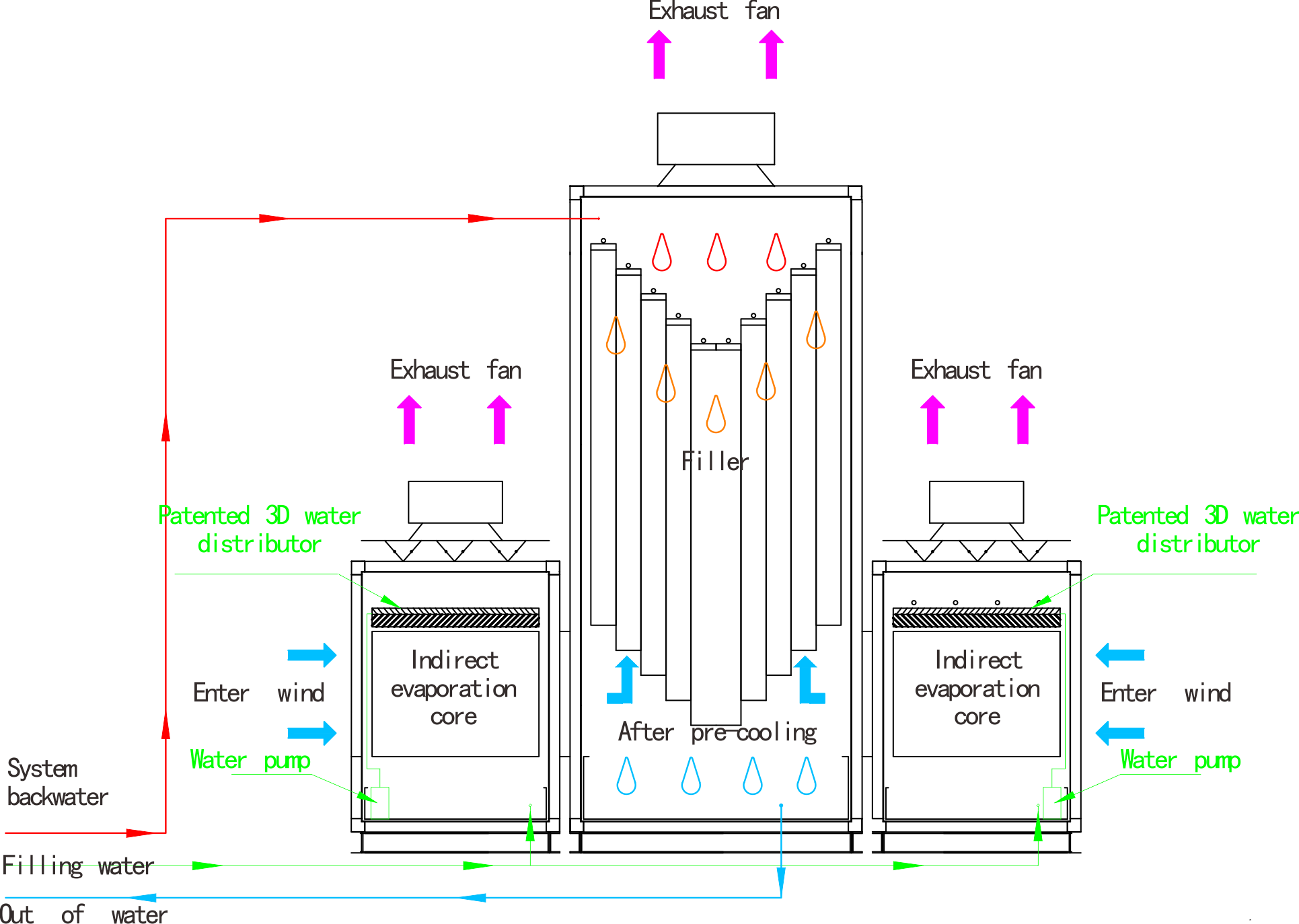

This product integration in cold type indirect evaporative, packing heat exchange, three dimension variable flow uniform water distribution, water quality real time detection processing and intelligent group control, a number of key technologies such as modular design, with high efficiency and energy saving, stable operation and prevent freezing and low noise characteristics, the fresh air, floor for dry areas public project cold radiation cooling application site, alternative mechanical refrigeration, The energy saving effect is very obvious. It is also very suitable for large data center new and old projects across the country.

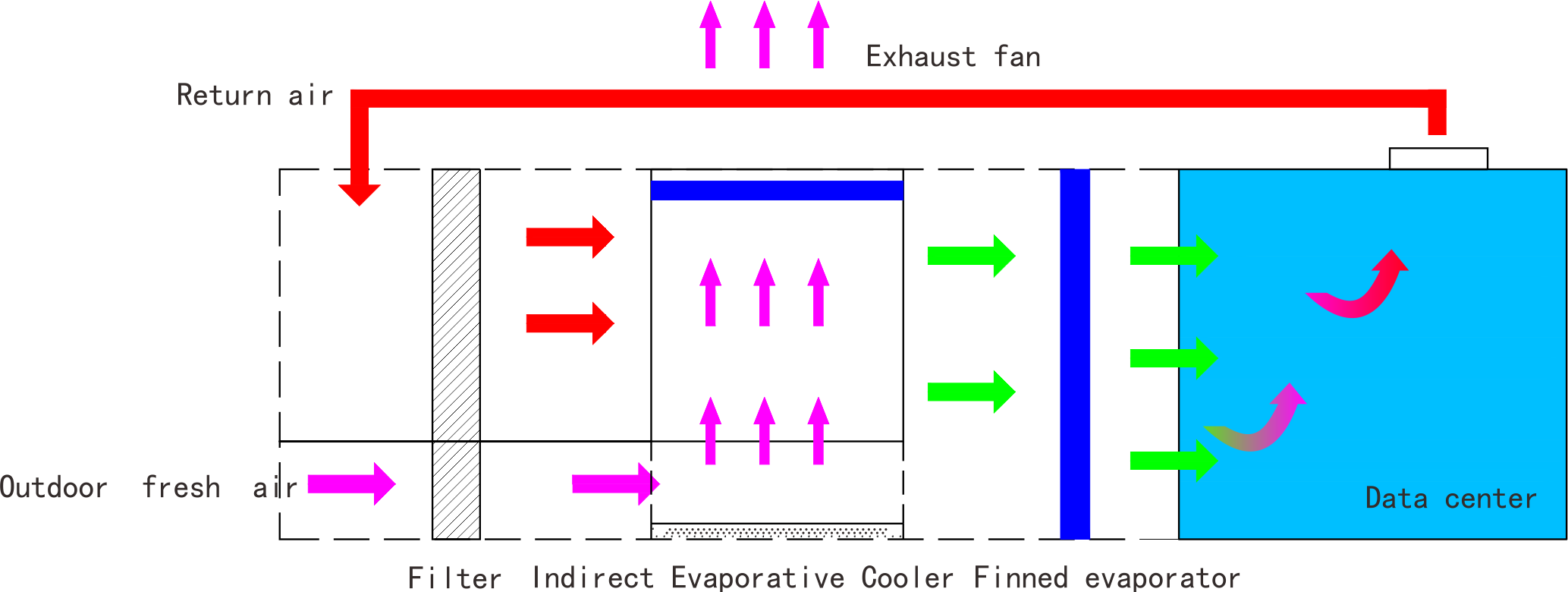

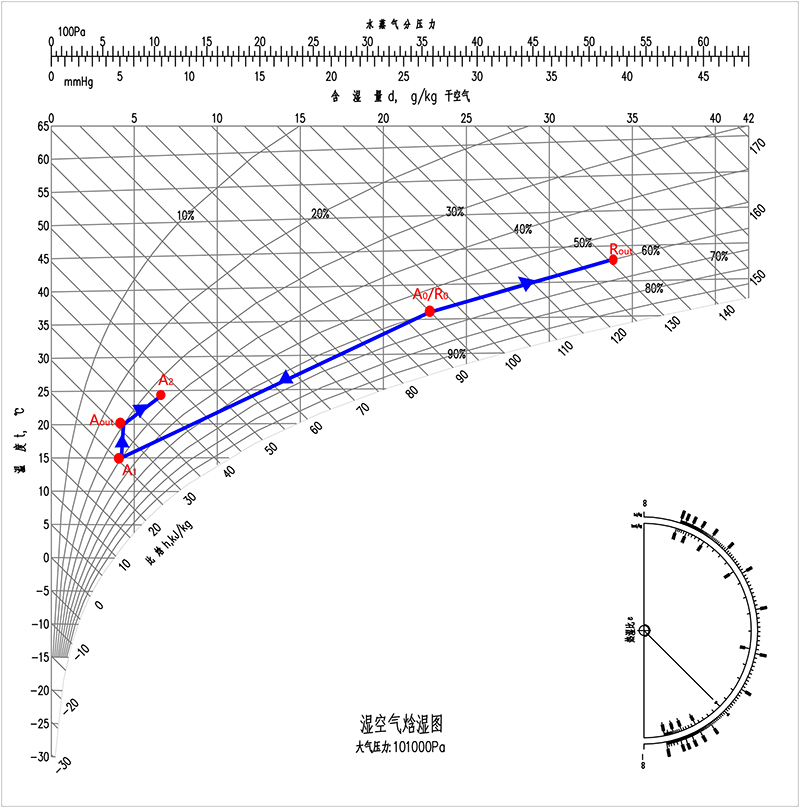

Working Principle

Features

1. Compared with mechanical refrigeration equipment, it can save energy by more than 65% under the same cooling capacity, greatly reducing operating costs.

2. The filler is made of organic polymer material, which has good flame retardant and antibacterial properties.

3. The filler adopts a new structure design, which can be quickly disassembled and replaced, effectively reducing the maintenance cost in the later period.

4. Adopts DC brushless EC fan, which has the characteristics of high reliability, high efficiency, long life, low vibration, low noise and uninterrupted operation, and can effectively prevent the intrusion of rain, snow and sand, and keep the water quality clean.

5. The whole machine adopts PLC and touch screen intelligent control, providing a variety of interface types. Real-time detection of water temperature, automatic control of fan speed.

6. The water tank is made of stainless steel, which has good rust and corrosion resistance. There is a quick access port for the water tank, which is convenient for water tank cleaning and component maintenance.

7. The inner-cooled indirect evaporative cooling core is made of high hydrophilic polymer material by special process, and adopts a wide-spaced plate-type structure, which has the advantages of high pressure difference without deformation, high heat exchange efficiency, corrosion resistance and long life. Features.

8. Large aperture three-dimensional water distribution technology, uniform water distribution, not easy to block; patented structure design, more suitable for variable flow operation.

9. The mechanical strength of the box body reaches European standards; the thermal insulation panel adopts new energy-saving materials that are safe and environmentally friendly.

10. The unit has complete protection functions, providing alarm functions such as power phase loss, undervoltage, antifreeze, and abnormal liquid level.

Application

Data centers, hospitals, schools, airports, high-speed rail, shopping malls, libraries, gymnasiums, exhibition halls, etc.

Optional Function (Non-Standard)

1. Intelligent group control function: group control, realize intelligent group control with 40 devices.

2. Water softening system: It can be selected in areas with hard water quality, which can effectively remove calcium and magnesium ions in the water, reduce maintenance workload, and prolong the life of the unit.

3. Built-in board replacement and primary pump system: realize rapid on-site layout and reduce engineering volume.

4. Built-in mechanical refrigeration system: Compensate for insufficient cooling capacity of natural cold source.

5. Circulating water descaling, filtration and sterilization devices: maintain the cleanliness of circulating water.

6. Antifreeze device: avoid freezing of water in the water tank due to low ambient temperature.

7. Lightning protection and surge protection device: avoid the interference and impact of lightning and equipment on the power grid.

Specification

| Model | AGS40 (Single module) | AGS50 (Single module) | AGS80 (Single module) | AGS100 (Single module) | AGS150 (Single module) | AGS200 (Single module) |

| Maximum Circulating Water Volume (m³/h) | 40 | 50 | 80 | 100 | 150 | 200 |

| Supply and Return Water Temperature Difference (℃) | 3/5/10 | 3/5/10 | 3/5/10 | 3/5/10 | 3/5/10 | 3/5/10 |

| Max Power (kW) | 18 | 22 | 35 | 41 | 62 | 80 |

| Max Noise (dB(A)) | 74 | 75 | 78 | 80 | 82 | 85 |

For specific performance parameters, dimensions and non-standard conditions, please contact the technical department.

Project Cases

![]() Gymnasium canteen application case

Gymnasium canteen application case

![]() Data room ventilation and cooling

Data room ventilation and cooling

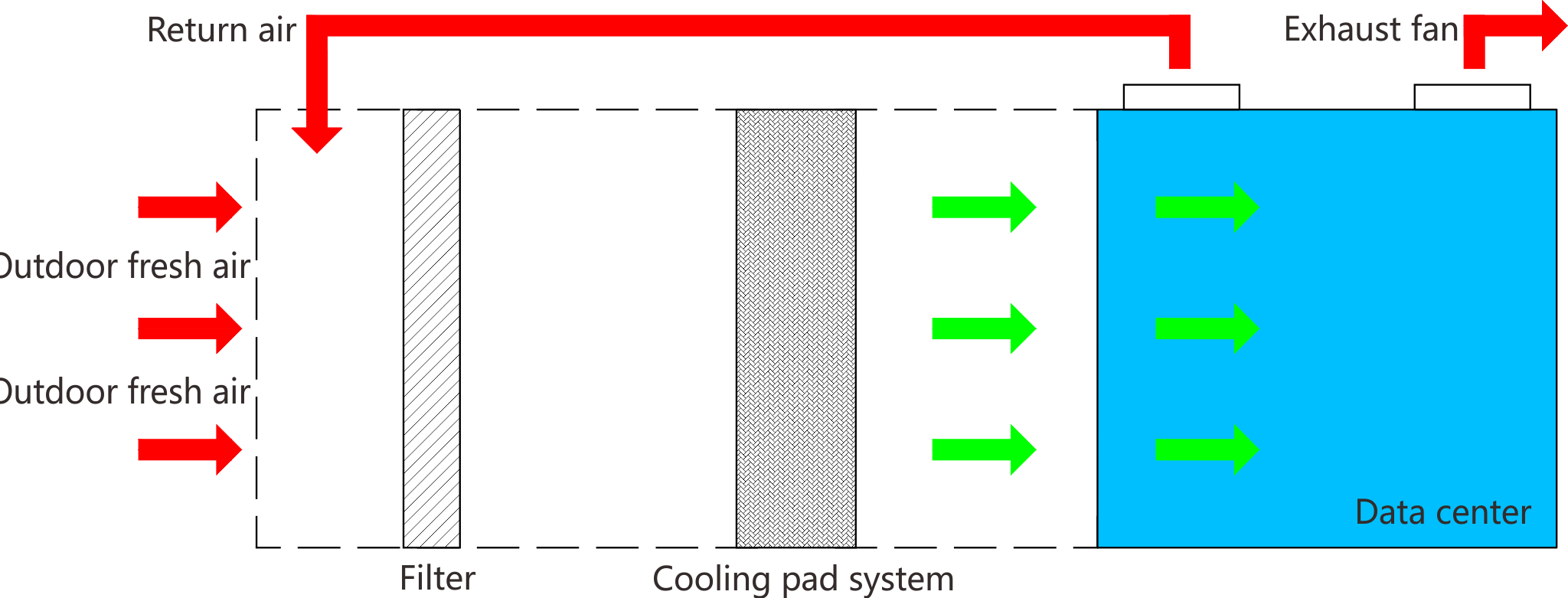

Overview

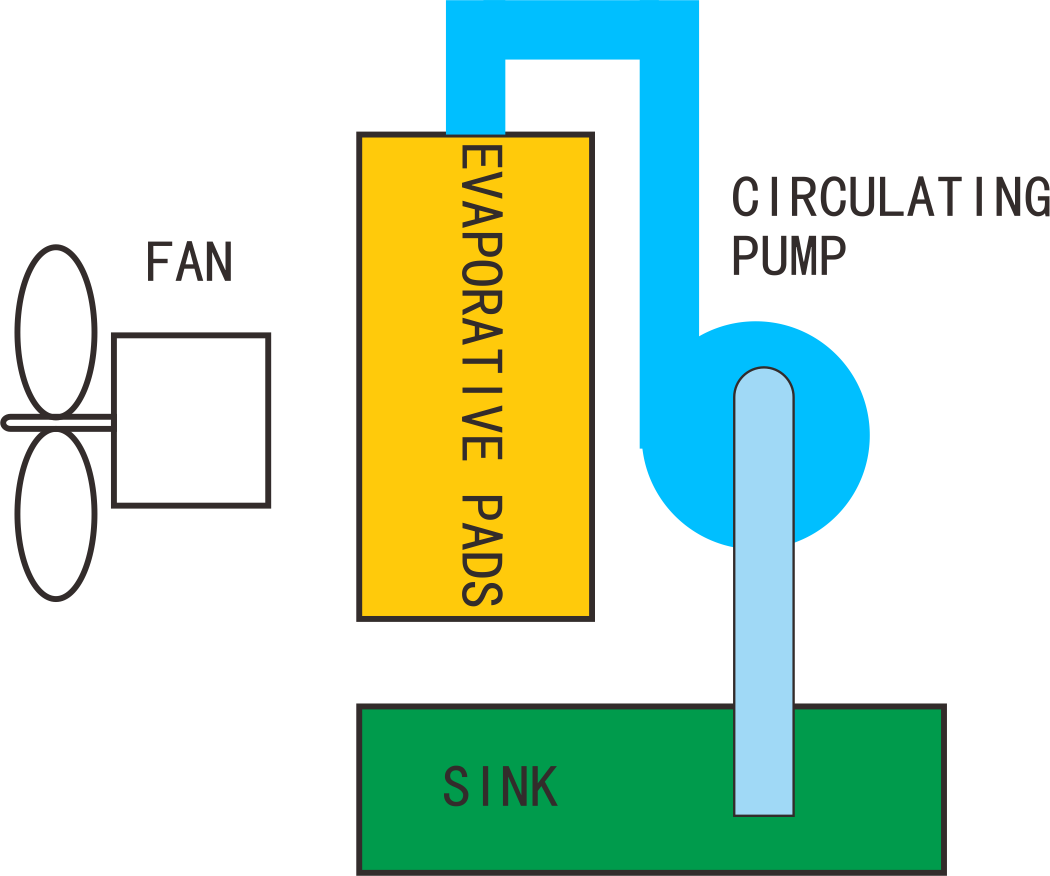

1. Evaporative cooling pad system uses the principle of evaporative cooling of water, absorbs the heat in the air through the evaporation of water, and cools the air with enthalpy.

2. The cooling pad wall is mainly composed of the cooling pad body, the outer frame, the circulating water system, the controller, etc. It is usually used in conjunction with the negative pressure fan. The outdoor dry hot air passes through the wet cooling pad surface under the suction of the negative pressure fan. The evaporation of water in the cooling pad continuously absorbs the heat in the air. The air is cooled by heat absorption and sent to the room, mixed with the hot and humid air in the room, and then exhausted through negative pressure and discharged to the outside. At the same time, the dust in the air will also be adsorbed and discharged by the cooling pad, so as to keep the indoor fresh and cool environment.

Advantages

1. Cooling pad

● 7090 wet film is generally used in agriculture and animal husbandry. Commonly used thicknesses are 100mm and 150mm.

● Adopt imported virgin pulp long fiber material, which has good water absorption performance and high evaporation efficiency.

● Refined without phenol glue, environmentally friendly, no pungent odor, no harm to animals and plants.

● High wet stiffness, firm and not deformed, and long service life.

2. Frame and sink

● There are various options such as aluminum alloy professional profiles, stainless steel, galvanized sheet + spraying for the outer frame.

● Forming sinks of different materials such as aluminum alloy, stainless steel and PVC are optional.

● Stainless steel rodent-proof net to prevent rodents from biting the cooling pad.

3. Circulating water system

● High-quality self-priming circulating water pump to ensure long-term use.

● Outdoor sun-resistant special water pipe, the original water distribution system design, to ensure that the cooling pad is fully wet, and there is no dry area.

● Large filter design to ensure water quality.

● Automatic water replenishment device to ensure a certain water level in the water tank to avoid dry burning of the pump.

Application

It is suitable for supporting use of fresh air and humidification systems such as pig houses and chicken houses in animal husbandry, greenhouses in planting industry, and industrial large-space workshops.

Working Principle

Note: Affected by ambient temperature and humidity in different regions, the cooling effect will be different.

Project Cases

![]() Flower planting greenhouse ventilation

Flower planting greenhouse ventilation

![]() Vegetable and fruit greenhouse ventilation and cooling case

Vegetable and fruit greenhouse ventilation and cooling case

![]() Animal husbandry & Flower planting ventilation and cooling

Animal husbandry & Flower planting ventilation and cooling

![]() Cattle farm ventilation and cooling

Cattle farm ventilation and cooling

![]() Chicken farm ventilation and cooling

Chicken farm ventilation and cooling

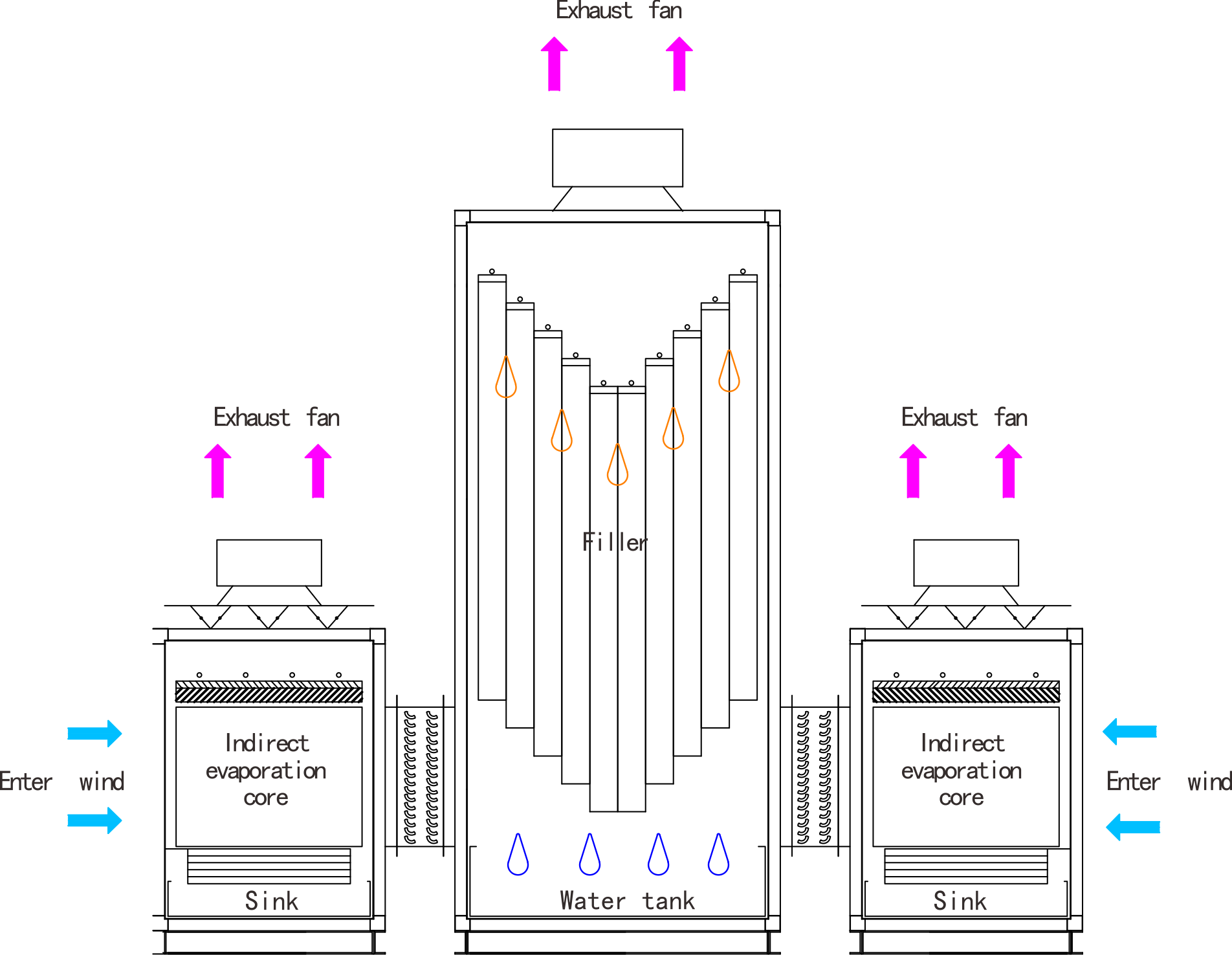

Overview

This product integrates a number of key technologies such as internal cooling indirect evaporation, external cooling indirect evaporation, filler heat and moisture exchange, three-dimensional variable flow uniform water distribution, real-time water quality detection and processing, and intelligent group control. , low noise and modularity, it can completely replace mechanical refrigeration for applications such as fresh air treatment and floor cooling radiation cooling systems in public construction projects in dry areas, and the energy saving effect is very obvious.

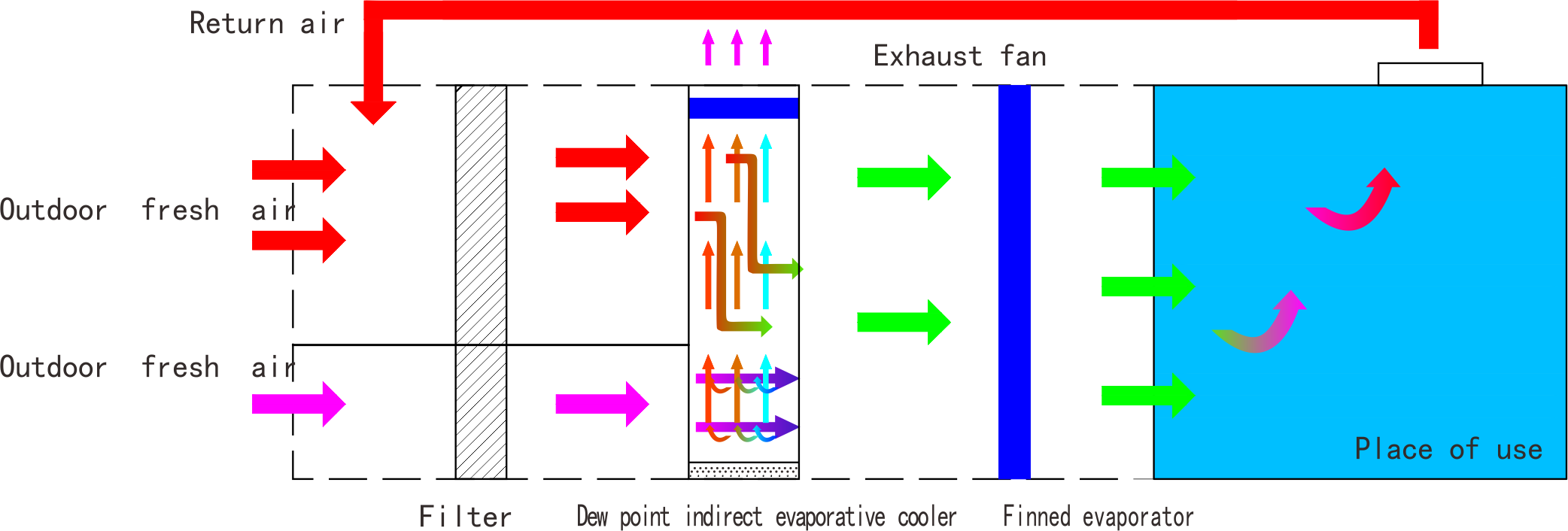

Working Principle

Features

1. Compared with mechanical refrigeration equipment, it can save energy by more than 65% under the same cooling capacity, greatly reducing operating costs.

2. The filler is made of organic polymer material, which has good flame retardant and antibacterial properties.

3. The filler adopts a new structure design, which can be quickly disassembled and replaced, effectively reducing the maintenance cost in the later period.

4. Adopts DC brushless EC fan, which has the characteristics of high reliability, high efficiency, long life, low vibration, low noise and uninterrupted operation, and can effectively prevent the intrusion of rain, snow and sand, and keep the water quality clean.

5. The whole machine adopts PLC and touch screen intelligent control, providing a variety of interface types. Real-time detection of water temperature, automatic control of fan speed.

6. The water tank is made of stainless steel, which has good rust and corrosion resistance. There is a quick access port for the water tank, which is convenient for water tank cleaning and component maintenance.

7. The inner-cooled indirect evaporative cooling core is made of high hydrophilic polymer material by special process, and adopts a wide-spaced plate-type structure, which has the advantages of high pressure difference without deformation, high heat exchange efficiency, corrosion resistance and long life. Features.

8. Large aperture three-dimensional water distribution technology, uniform water distribution, not easy to block; patented structure design, more suitable for variable flow operation.

9. The mechanical strength of the box body reaches European standards; the thermal insulation panel adopts new energy-saving materials that are safe and environmentally friendly.

10. The unit has complete protection functions, providing alarm functions such as power phase loss, undervoltage, antifreeze, and abnormal liquid level.

Application

Data centers, hospitals, schools, airports, high-speed rail, shopping malls, libraries, gymnasiums, exhibition halls, etc.

Optional Function (Non-Standard)

1. Intelligent group control function: group control, realize intelligent group control with 40 devices.

2. Water softening system: It can be selected in areas with hard water quality, which can effectively remove calcium and magnesium ions in the water, reduce maintenance workload, and prolong the life of the unit.

3. Built-in board replacement and primary pump system: realize rapid on-site layout and reduce engineering volume.

4. Built-in mechanical refrigeration system: Compensate for insufficient cooling capacity of natural cold source.

5. Circulating water descaling, filtration and sterilization devices: maintain the cleanliness of circulating water.

6. Antifreeze device: avoid freezing of water in the water tank due to low ambient temperature.

7. Lightning protection and surge protection device: avoid the interference and impact of lightning and equipment on the power grid.

Specification

| Model | AGS40 (Single module) | AGS50 (Single module) | AGS80 (Single module) | AGS100 (Single module) | AGS150 (Single module) | AGS200 (Single module) |

| Maximum Circulating Water Volume (m³/h) | 40 | 50 | 80 | 100 | 150 | 200 |

| Supply and Return Water Temperature Difference (℃) | 3/5/10 | 3/5/10 | 3/5/10 | 3/5/10 | 3/5/10 | 3/5/10 |

| Max Power (kW) | 20 | 25 | 38 | 45 | 68 | 85.7 |

| Max Noise (dB(A)) | 74 | 75 | 78 | 80 | 82 | 85 |

For specific performance parameters, dimensions and non-standard conditions, please contact the technical department.

Project Cases

![]() Gymnasium Canteen Application Case

Gymnasium Canteen Application Case

![]() Data Room Ventilation and Cooling

Data Room Ventilation and Cooling

Overview

This product integrates multiple key technologies such as indirect evaporation, frequency conversion refrigeration, three-dimensional uniform water distribution, real-time water quality detection and processing, and intelligent group control. It adopts modular design and has the characteristics of high efficiency and energy saving, stable operation, anti-freezing and low noise. It can be used as a The independent cooling solution for new and old projects of the data center can also be used as a supplementary solution for the mechanical cooling of the data center, and the energy saving effect is very obvious. It is also suitable for energy saving and consumption reduction in various computer rooms and power distribution rooms.

Working Principle

Features

1. The inner frame structure has good air tightness and prevents cold bridges.

● High-pressure polyurethane insulation layer is used in the middle of the double-layer panel, and the thermal conductivity is less than 0.0195W/m2℃.

● The full panel is detachable, and there is a maintenance platform, which is convenient and simple to maintain.

● Segment (layer) structure design, no need for super high transportation, can be assembled on site to improve the quality of the whole machine.

2. The water system adopts double descaling, sterilization and purification treatment to ensure stable operation and long life of the unit.

3. The core body adopts a new structure design, which can be quickly disassembled and replaced, effectively reducing the maintenance cost in the later period.

4. The whole machine adopts PLC and touch screen intelligent control, providing a variety of interface types. Real-time detection of ambient temperature and humidity, automatic control of fan speed, the unit has functions such as filter dirty block alarm, automatic fan acceleration and long-life rotation.

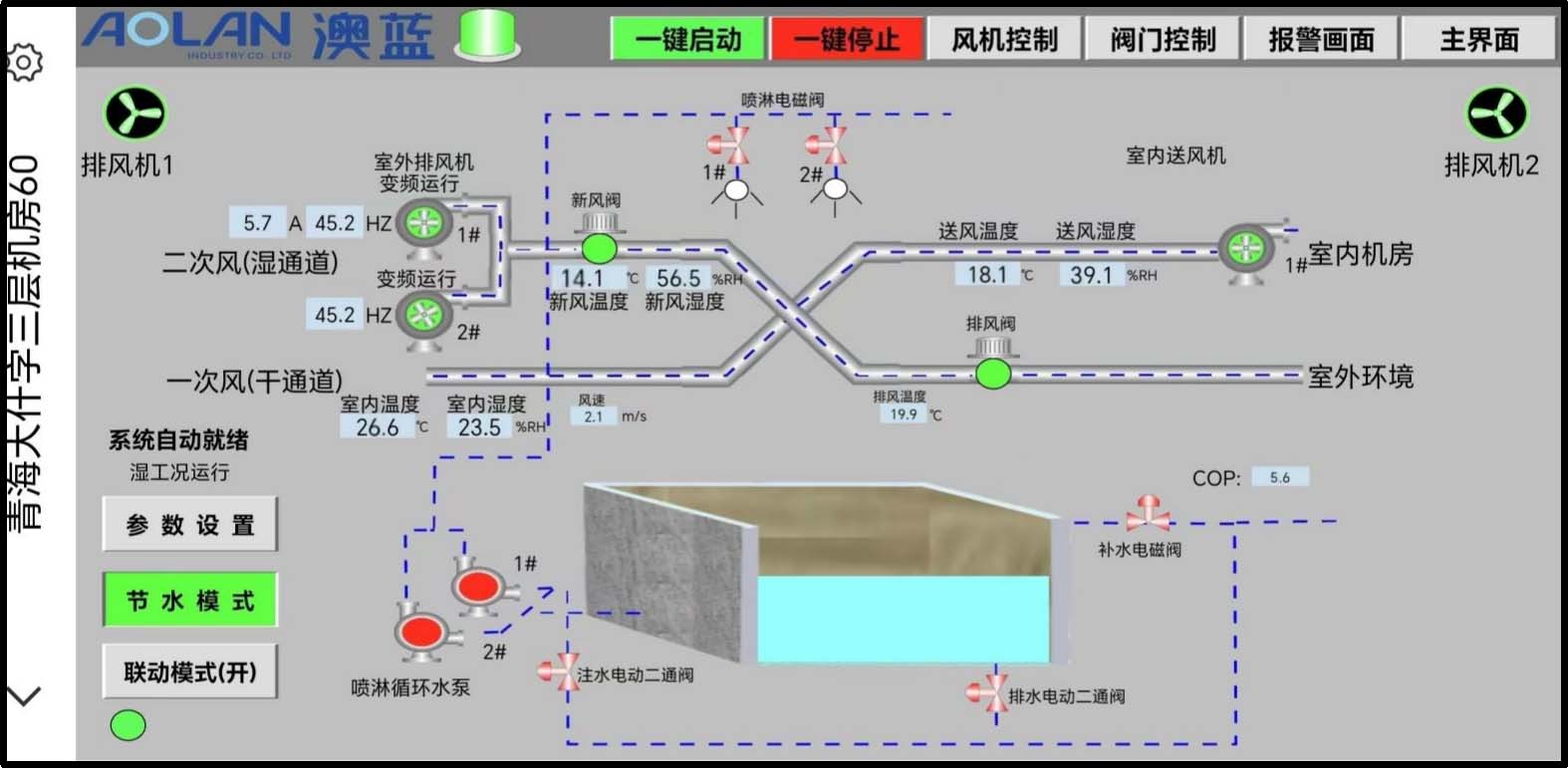

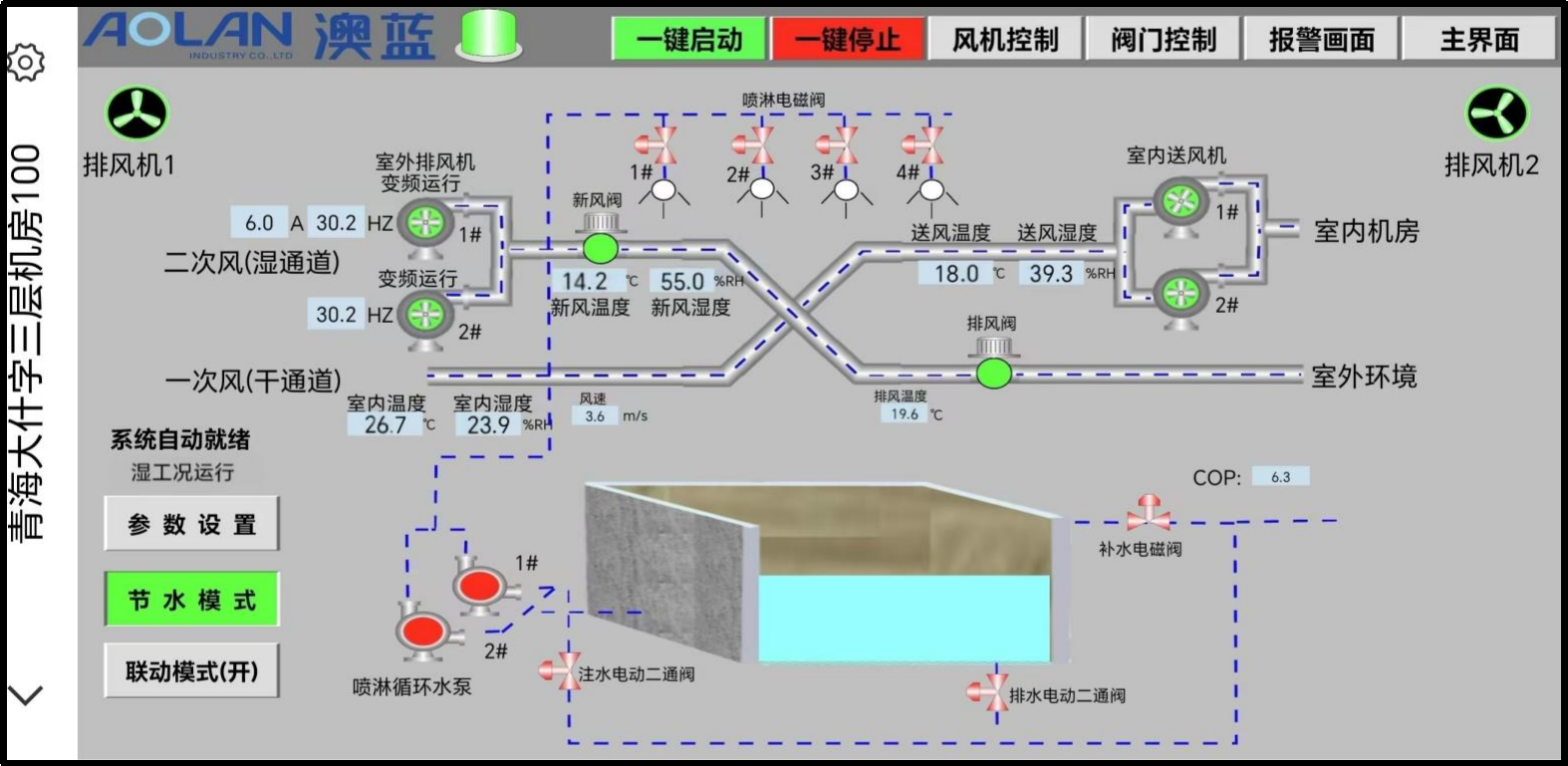

5. The unit can adopt three intelligent and efficient operation modes of dry working condition, wet working condition and composite working condition; it can also choose energy-saving mode, water-saving mode, economical mode and dehumidification mode to operate according to actual needs.

6. The unit reserves energy consumption collection interface, which can collect power consumption data in real time.

7. The indirect evaporative cooling core is made of high hydrophilic polymer material by special process, and adopts a wide-pitch plate structure, which is not deformed by high pressure difference, high heat exchange efficiency, corrosion resistance and long life, and self-cleaning Function.

8. Large-aperture three-dimensional water distribution, uniform water distribution, not easy to block, can be cleaned; flexible and precise water spraying, to prevent floating water leakage.

9. The unit adopts high-efficiency components from internationally renowned brands, and both the compressor and EC fan are variable frequency.

10. The unit adopts a power distribution structure in which the compressor supplies power alone, (fan + water pump) uses two circuits of electricity (at least one of which is U power), and two circuits of electricity are used for control (at least one of which is U power) to ensure the safety of data center electricity consumption. .

11. The unit has complete protection functions, providing alarm functions such as power phase loss, undervoltage, high and low voltage, overload, differential pressure, antifreeze, and abnormal liquid level.

Specification

| Model | ASK-J600 | ASK-J800 |

| Max Airflows (m³/h) | 60000 | 80000 |

| Supply/Return Air Emperature (℃) | 25/38 | 25/38 |

| Max Power (kW) | 30 | 40 |

| Max Residual Pressure (Pa) | 250 | 250 |

| Max mechanical supplemental cooling capacity | 80% | 80% |

For specific performance parameters, dimensions and use of non-standard working conditions, please contact the company's technical department.

Project Cases

Overview

The simple wet film humidifying media is a humidification component composed of a wet film, a water distributor, and an outer frame. Wet film humidifiers are the most energy-efficient humidifiers available and can replace electrode or electric heated humidifiers. As a core humidification and cooling component with low cost and low energy consumption, Aolan Wet Film Humidifying Media is widely used in humidification and cooling equipment such as industrial and commercial fields and data centers. It can also be used as air pre-cooling and cooling alone.

Features

1. The wet film made of imported long fiber grade original paddle has a water absorption efficiency of up to 250%, an evaporation efficiency of up to 95%, long life, no peculiar smell, no phenol and other harmful substances to the human body, and meets the requirements of environmental protection ROHS and REACH certification.

2. The outer frame, top cover, side plate and water receiving tray are made of 304 stainless steel with film or hot-dip galvanized material with anti-rust treatment to prolong the service life.

3. The water distribution pipe adopts CNC machine tools and special tooling drilling, with high machining accuracy, no burrs, and uniform aperture size.

4. The water distribution pipe is 100% leak-tight from the factory, and the wet film humidifier is 100% factory-dried to ensure the quality.

5. The wet film humidifier is produced by the countersunk riveting process, the surface has no scratches, is clean and bright.

6.The water distributor adopts copper pagoda head, and the tee, water pipe and plug are all made of high-quality PVC pipes to ensure high quality.

Optional Function (Non-Standard)

1. Intelligent group control function: group control, realize intelligent control of 40 devices with one belt.

2. Water softening system: It can be selected in areas with hard water, which can effectively remove calcium and magnesium ions in the water, reduce maintenance workload and prolong the life of the unit.

3. Circulating water descaling, filtration and sterilization devices: maintain the cleanliness of circulating water.

4. Fire curtain: polymer material or inorganic glass fiber material.

5. Frame material: stainless steel 304, aluminum or hot-dip galvanized material.

Application

The core components of the special refrigeration and humidification equipment for the communication field and data room, and the core components of the special equipment for energy-saving cooling in the scientific research office.

Specification

| Model | 5070 (Single Module) | 5090 (Single Module) | 6090 (Single Module) | 7090 (Single Module) |

| Humidifying Capacity (kg/h) | ≤160 | ≤160 | ≤160 | ≤160 |

| Cooling Pad Width (mm) | ≤1100 | ≤1100 | ≤1100 | ≤1100 |

| Cooling Pad Height (mm) | ≤2000 | ≤2000 | ≤2000 | ≤2000 |

| Cooling Pad Thickness (mm) | ≤400 | ≤400 | ≤400 | ≤400 |

For specific performance parameters, dimensions and non-standard customization, please contact the company's technical department.

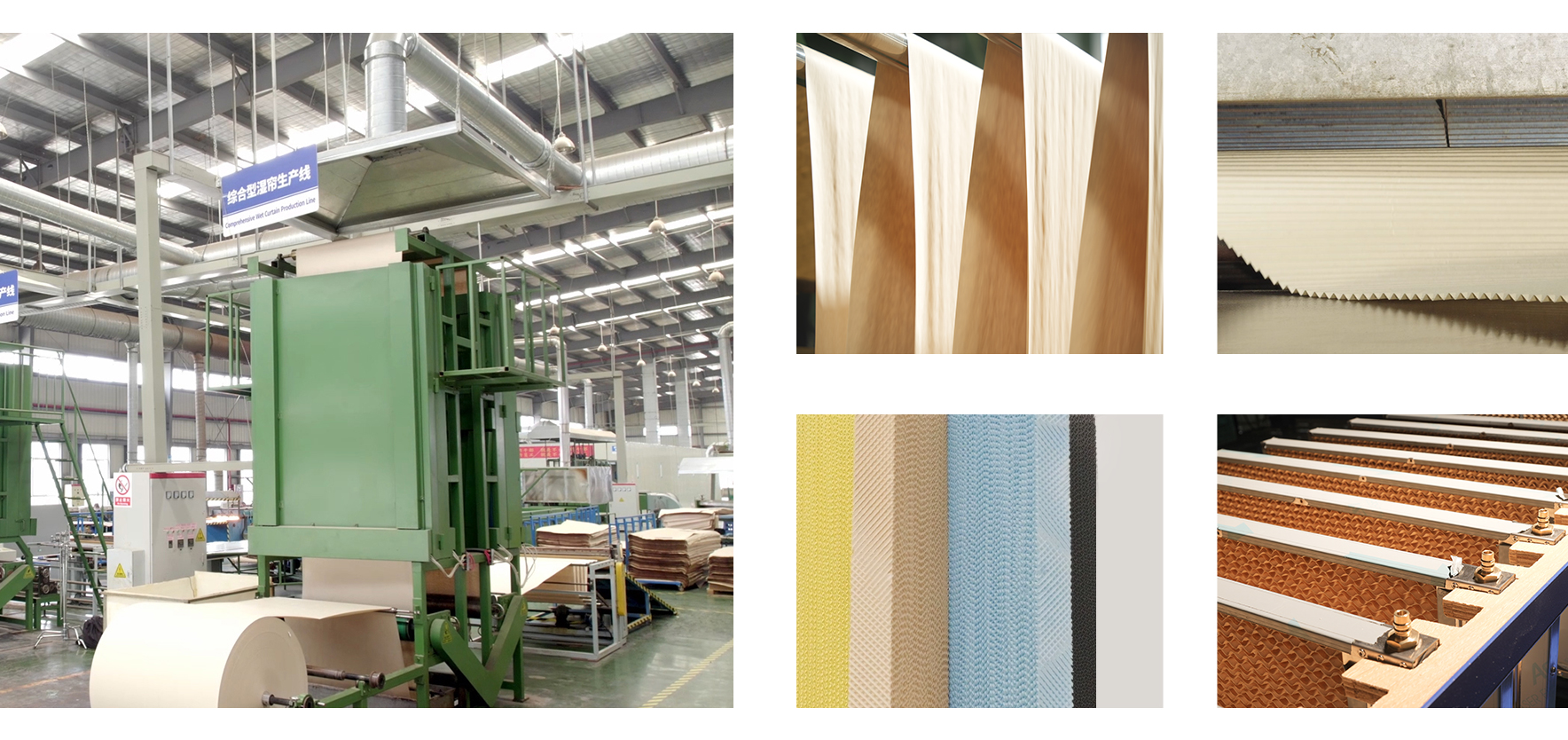

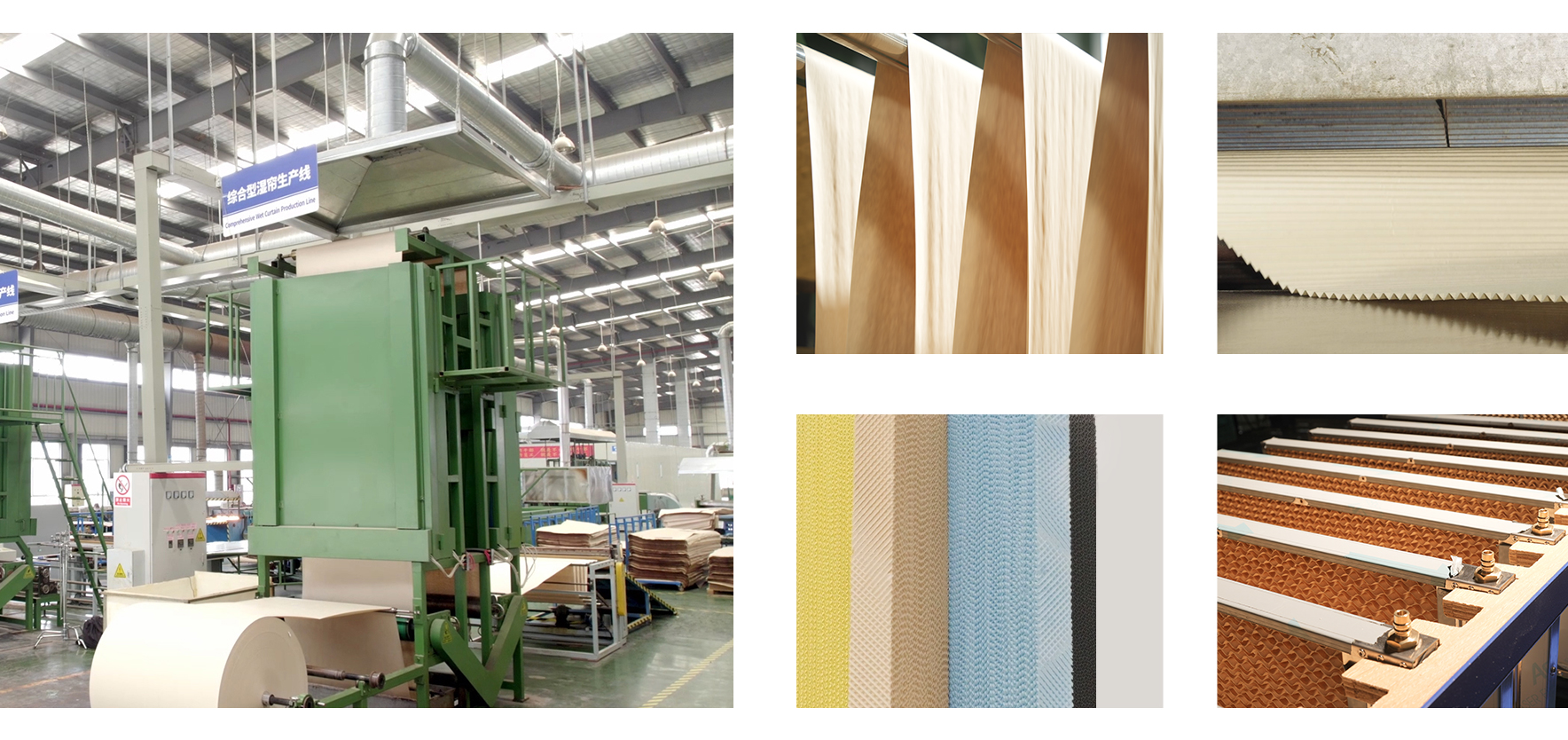

List Of Production

Overview

The fire-resistant and flame-retardant wet curtain produced by Aolan Company is made of imported polymer materials through special processing, does not contain glass fiber, and has the characteristics of high wet stiffness, high evaporation efficiency, low resistance and environmental protection. The core supporting components of evaporation equipment are widely used, especially in the wet film humidifier in the data room, the cooling of power plant equipment and the cooling of subway fresh air and other equipment or fields.

Features

1. Special polymer material, high water absorption, high chemical stability, acid and alkali resistance, strong weather resistance, never rot.

2. Permanent B1 flame retardant, water absorption efficiency up to 250%, evaporation efficiency up to 95%.

3. The use of environmentally friendly glue, no odor, no phenol and other harmful substances to the human body.

4. The main materials and auxiliary materials used are all environmentally friendly materials, which meet the requirements of environmental protection ROHS and REACH certification

5. Each process is carefully manufactured, and quality inspection is strictly implemented to ensure quality.

6. Patented high-precision cutting equipment, small tolerance, no burr, beautiful appearance.

7. Patented formula, antibacterial and mildew proof authoritative certification.

Application

It is used in communication equipment rooms, data centers, and special industrial fields as the core components of humidification and flame retardant.

Specification

| Model | 5070 (Single Module) | 5090 (Single Module) | 7090 (Single Module) |

| Maximum Humidifying Capacity (kg/h) | ≤160 | ≤160 | ≤160 |

| Highest Efficiency | ≤95% | ≤95% | ≤95% |

| Max Width (mm) | ≤1000 | ≤1000 | ≤1000 |

| Max Height (mm) | ≤1000 | ≤1000 | ≤1000 |

| Max Thickness (mm) | ≤300 | ≤300 | ≤300 |

For specific performance parameters, dimensions and non-standard customization, please contact the company's technical department.

List Of Production

Overview

The cooling pads produced by Aolan Company are made of imported long-fiber grade original paddles and processed by special technology. It has the characteristics of high wet stiffness, high evaporation efficiency, low resistance and environmental protection. It is widely used as the core component of evaporative cooling and humidification equipment, especially in evaporative air conditioners, wet film humidifiers in data rooms, and animal husbandry. The wet curtain wall and other fields are the most widely used.

Features

1. The cooling pad made of imported long fiber grade original paddle has a water absorption efficiency of up to 250% and an evaporation efficiency of up to 95%.

2. The use of environmentally friendly glue, no odor, no phenol and other harmful substances to the human body.

3. The main materials and auxiliary materials used are environmentally friendly materials, which meet the requirements of environmental protection ROHS and REACH certification.

4. Each process is carefully manufactured, and quality inspection is strictly implemented to ensure quality.

5. Patented high-precision cutting equipment, with small tolerances, no burrs, and beautiful appearance.

6. Patented formula, antibacterial and mildew proof authoritative certification.

Application

The core component of all evaporative cooling and humidification equipment.

Specification

| Model | 5070 (Single Module) | 5090 (Single Module) | 6090 (Single Module) | 7090 (Single Module) |

| Maximum Humidifying Capacity (kg/h) | ≤160 | ≤160 | ≤160 | ≤160 |

| Highest Efficiency | ≤95% | ≤95% | ≤95% | ≤95% |

| Max Width (mm) | ≤1000 | ≤1000 | ≤1000 | ≤1000 |

| Max Height (mm) | ≤1000 | ≤1000 | ≤1000 | ≤1000 |

| Max Thickness (mm) | ≤400 | ≤400 | ≤400 | ≤400 |

The data is for reference only. For specific performance parameters, dimensions and non-standard customization, please contact the company's technical department.

Overview

Aolan indirect evaporation core is made of nano-scale high hydrophilic film and polymer material by special welding process, which is resistant to high and low temperature, firmly attached, small thermal resistance, and high heat exchange efficiency; The glue filling process has the characteristics of high strength, good sealing performance, high heat exchange efficiency, corrosion resistance and long life. It is mainly used for new return air cooling and heat recovery in dry areas; The core components of indirect evaporative high temperature chillers and fresh air ventilators are used together.

Features

1. The polymer heat exchange plate has high water absorption and good evaporative cooling effect.

2. Strong corrosion resistance and weather resistance, high structural strength and good sealing performance.

3. Washable, long service life.

4. Core size can be customized according to customer requirements.

5. The structure can be modularized, which is convenient for on-site assembly.

6. All materials used are environmentally friendly materials.

Optional Function (Non-Standard)

1. Water spray system: three-dimensional water distribution or sprinkler water.

2. Water softening system: optional in areas with hard water quality, it can effectively remove calcium and magnesium ions in water, reduce maintenance workload and prolong unit life.

3. Frame material: stainless steel 304, aluminum or hot-dip galvanized material.

Application

The core parts of the special equipment for dual-channel cooling and ventilation are adopted.

Specification

| Model | L*W*H (Single Module) |

| Pitch of Fins (mm) | 4、6、10 |

| Max Length (mm) | ≤2000 |

| Max Width (mm) | ≤1500 |

| Max Height (mm) | ≤1000 |

For specific performance parameters, dimensions and non-standard customization, please contact the company's technical department.

Overview

The extraction fan is to discharge the indoor air at high temperature and turbidity, and use the principle of atmospheric pressure difference to humidify and cool the outdoor air through the water curtain and then send it indoors to provide a comfortable production environment for indoor animals and plants.

FRP Extraction Fan

Advantages

1.Communication Internet of Things access, realize remote control, infinitely variable speed.

2.Customized composite fan blades are lighter, reduce motor load, have more toughness, anti-fatigue, improve ventilation effect, and reduce noise.

3.Equipped with high-performance fan blades, which greatly reduces energy consumption.

Specification

| Model | AFY24- L4B740Z | AFY24- L3B740Z | AFY36- L3B1180Z | AFY36- N3B1180Z | AFY36- N5B1180G | AFY36- N6B1180G | AFY51- L3B1480Z | AFY51- N3B1480Z | AFY55- N3B1630Z |

Max Airflows (m³/h) | 11160 | 11110 | 23170 | 24110 | 35290 | 30030 | 46000 | 45270 | 58400 |

Hole of Install (mm) | 740*740 | 740*740 | 1180*1180 | 1180*1180 | 1180*1180 | 1180*1180 | 1480*1480 | 1480*1480 | 1630*1630 |

| Blade Size (mm) | 610 | 610 | 920 | 920 | 920 | 920 | 1290 | 1290 | 1390 |

| Motor Power (W) | 375 | 375 | 550 | 550 | 2200 | 2200 | 1200 | 1200 | 1500 |

| Motor Drive Method | Direct Drive | Direct Drive | Direct Drive | Direct Drive | Direct Drive | Direct Drive | Direct Drive | Direct Drive | Direct Drive |

Sheet Metal Extraction Fan

Advantages

1. Humanized design pull ring, pull the shutter and fix it at 90 degrees, and realize non-electric ventilation through the auxiliary function of the pull ring weight.

2. The pure copper core wire motor has low temperature rise, small noise, stable operation and long life.

3. The U-shaped stamping stainless steel fan blades have high toughness, low noise, stable operation and long service life.

4. The design of the armrest is user-friendly, which is convenient to lift or move.

Specification

| Model | AFY28-G6X800P | AFY30-G6X900P | AFY38-G6X1060P | AFY43-G6X1220P | AFY50-G6X1380P | AFY55-G6X1530P |

| Hole of Install (mm) | 800*800 | 900*900 | 1060*1060 | 1220*1220 | 1380*1380 | 1530*1530 |

| Blade Size (mm) | 710 | 750 | 960 | 1100 | 1250 | 1400 |

| Power (W) | 370 | 370 | 550 | 750 | 1100 | 1500 |

| Moto Drive Method | Belts | Belts | Belts | Belts | Belts | Belts |

| Airflows (m³/h) | 20000 | 22000 | 29000 | 38000 | 44000 | 5580 |

| Residual Pressure (Pa) | 70 | 65 | 70 | 73 | 56 | 60 |

Anti-Corrosion Extraction Fan

Advantages

1. The anti-corrosion material of the outer frame does not rust, and the service life is more than 10 years.

2. The motor and the impeller have high concentricity, and the belt is not easy to wear.

3. The motor plate chute is designed for easy adjustment of the belt.

4. The noise is low and the vibration is small, and the air supply is far and concentrated.

5. Easy to disassemble and maintain.

Specification

| Model | AFY50-G6S1380P | AFY43-G6S1220P | AFY38-G6S1060P | AFY30-G6S900P |

| Power (W) | 1.1 | 0.75 | 0.55 | 0.37 |

| Max Airflows (m³/h) | 44500 | 37000 | 32000 | 27000 |

| Noise (dB(A)) | ≤65 | ≤63 | ≤60 | ≤56 |

| Rated Voltage/Frequency | 380V/50Hz | 380V/50Hz | 380V/50Hz | 380V/50Hz |

| Motor Driver Method | Belts | Belts | Belts | Belts |

| Blade Speed | 480RPM | 580RPM | 530RPM | 580RPM |

| Dimension (mm) | 1380*1380*400 | 1220*1220*400 | 1060*1060*400 | 900*900*400 |

| Model | AFY50-G6S1380Z | AFY43-G6S1220Z | AFY38-G6S1060Z | AFY30-G6S900Z |

| Power (W) | 1.1 | 0.75 | 0.55 | 0.37 |

| Max Airflows (m³/h) | 44500 | 40000 | 34000 | 30000 |

| Noise (dB(A)) | ≤70 | ≤68 | ≤65 | ≤60 |

| Rated Voltage/Frequency | 380V/50Hz | 380V/50Hz | 380V/50Hz | 380V/50Hz |

| Motor Driver Method | Direct Drive | Direct Drive | Direct Drive | Direct Drive |

| Blade Speed | 580RPM | 580RPM | 580RPM | 730RPM |

| Dimension (mm) | 1380*1380*400 | 1220*1220*400 | 1060*1060*400 | 900*900*400 |

Application

Negative pressure fans are widely used in the new expansion or renovation of animal husbandry, flowers, and vegetable greenhouses.

Overview

This product integrates a number of key technologies such as external cooling indirect evaporation, filler heat and moisture exchange, three-dimensional variable flow uniform water distribution, real-time water quality detection and processing, and intelligent group control. Features such as low noise, can replace mechanical refrigeration for applications such as fresh air treatment of public construction projects in dry areas, floor cold radiation cooling, etc., with obvious energy-saving effect, and it is also very suitable for energy-saving and cooling of large data centers.

Working Principle

Features

1. Compared with mechanical refrigeration equipment, it can save energy by more than 70% under the same cooling capacity and greatly reduce operating costs.

2. The filler is made of organic polymer material, which has good flame retardant and antibacterial properties.

3. The packing adopts a new structure design, which can be quickly disassembled and replaced, effectively reducing the maintenance cost in the later period.

4. It adopts DC brushless EC fan, which has the characteristics of high reliability, high efficiency, long life, low vibration, low noise and uninterrupted operation, and can effectively prevent the intrusion of rain, snow and sand, and keep the water quality clean.

5. The whole machine adopts PLC and touch screen intelligent control, providing a variety of interface types. Real-time detection of water temperature, automatic control of fan speed.

6. The water tank is made of stainless steel, which has good rust and corrosion resistance. There is a quick access port for the water tank, which is convenient for water tank cleaning and component maintenance.

7. The external cooling indirect evaporative pre-cooling coil adopts patented structure design to ensure clean drainage and prevent freezing and cracking in winter.

8. Large aperture three-dimensional water distribution technology, uniform water distribution, not easy to block; patented structure design, more suitable for variable flow operation.

9. The mechanical strength of the box body reaches European standards; the thermal insulation panel adopts new energy-saving materials that are safe and environmentally friendly.

10. The unit has complete protection functions, providing alarm functions such as power phase loss, undervoltage, antifreeze, and abnormal liquid level.

Application

Data centers, hospitals, schools, airports, high-speed rail, shopping malls, libraries, gymnasiums, exhibition halls, etc.

Optional Function (Non-Standard)

1. Intelligent group control function: group control, realize intelligent group control with 40 devices.

2. Water softening system: optional in hard areas, it can reduce the calcium ions in the site, reduce the maintenance workload, and effectively prolong the life of the labor force.

3. Combination plate replacement and one-time pumping system: realize fast on-site and reduce engineering quantity.

4. Combined mechanical refrigeration system: It proves that the cooling capacity of natural cold source is insufficient.

5. Circulating water descaling, filtration and fermentation devices: maintain the cleanliness of circulating water.

6. Antifreeze device: avoid the freezing of water in the water tank caused by the environment.

7. Lightning protection and surge protection device: lightning and equipment will not interfere with the impact of the power grid.

Specification

| Model | AGS40 (Single module) | AGS50 (Single module) | AGS80 (Single module) | AGS100 (Single module) | AGS150 (Single module) | AGS200 (Single module) |

| Maximum Circulating Water Volume (m³/h) | 40 | 50 | 80 | 100 | 150 | 200 |

| Supply and Return Water Temperature Difference (℃) | 3/5/10 | 3/5/10 | 3/5/10 | 3/5/10 | 3/5/10 | 3/5/10 |

| Max Power (kW) | 10 | 12 | 18 | 25 | 35 | 50 |

| Max Noise (dB(A)) | 72 | 73 | 76 | 78 | 80 | 83 |

For specific performance parameters, dimensions and use of non-standard working conditions, please contact the company's technical department.

Project Cases

![]() Gymnasium Canteen Application Case

Gymnasium Canteen Application Case

![]() Data Room Ventilation and Cooling

Data Room Ventilation and Cooling

Overview

Utilize the inclination of the funnel to defecate directly into the main pipeline, and directly collect it into the septic tank for centralized treatment through the flushing of urine and water. There is no ammonia backflush in the pig house to achieve a comfortable production environment.

Advantages

1. Abandon the original traditional manure tank and manure ditch, replace the original manure scraping equipment, and save floor space.

2. Reduce construction and later manual scraping costs.

3. Fewer urine and feces residues, low ammonia concentration in poultry houses, less mosquitoes, and a comfortable environment conducive to animal growth.

4. Using ionic material, long service life.

Application

It is widely used in the new expansion or renovation of pig houses in the breeding industry, and provides solutions for saving space for the floor breeding industry.

Features

1. Using plastic or glass fiber reinforced plastic chassis, stainless steel and galvanized sheet shell, the overall structure is solid, high strength and corrosion resistance.

2. Using double inlet forward centrifugal fan with large airflow, big air pressure and long drive distance.

3. The centrifugal fan with high efficiency, low noise, flat performance curve and wide high-efficiency area.

4. Using three-phase two-speed or variable frequency speed regulation motor, with good heat dissipation, waterproof, anti-corrosion, low noise and small vibration.

5. Using a unique water distributor, the water flow is even and smooth, and it is not easy to block.

6. Using high efficiency evaporative pads, good cooling effects and easy to clean.

Application

Tall spaces, large factories (automobile factories, machinery factories, logistics and warehousing), public buildings (gymnasiums, libraries, high-speed railway stations, airports), commercial buildings (commercial plazas, large supermarkets, farmers markets).

Specification

| Model/Specs | AZL60-LX32D AZL60-LS32D AZL60-LC32D | AZL80-LC32B |

| X-down discharge, S-up discharge, C-side discharge | ||

| Electrial Source | 380-415/50-60(V/Hz) 3-phase | 380-415/50-60(V/Hz) 3-phase |

| Power (kW) | 18.5/6 | 30/15 |

| Rated Current (A) | 37/15.7 | 61.7/33.6 |

| Airflows (m³/h) | 60000/36000 | 80000/58000 |

| Fan Type | Centrifugal | Centrifugal |

| Fan Speed | 3-phase, 2-speed | 3-phase, 2-speed |

| Pressure (Pa) | 520/242 | 700/480 |

| Vent Size (L*W) (mm) | 810*956 | 1355*1042 |

| Noise (dB(A)) | ≤83 | ≤91 |

| Dimension (L*W*H) (mm) | 2088*2070*1863 (down) 2088*2070*2011 (up) 2172*2070*1863 (side) | 3103*2202*2400 |

| Pad Size (L*W*H) (mm) | 1555*860*120 | 3103*2202*2400 |

| Aluminum Alloy Shell | Optional | Optional |

| Net Weight (±3Kg) | 900 | 1600 |

| Operatlon Weight (kg) | 1000 | 1762 |

| Controller | Button+Knob Switch | Button+Knob Switch |

| QTY/Full (40HQ) | 5 | 3 |

Note: The actual air volume is related to the outlet static pressure (air duct resistance). For details, please consult the company's technical department.

Overview

This product integrates multiple key technologies such as indirect dew point evaporation, three-dimensional uniform water distribution, real-time water quality detection and processing, and intelligent group control. It adopts modular design and has the characteristics of high efficiency and energy saving, stable operation, anti-freezing and low noise, and can be used in dry areas. The fresh air cooling of public construction projects can replace the use of mechanical refrigeration, and the energy saving effect is very obvious. It is also suitable for energy-saving and cooling of various computer rooms and power distribution rooms.

Working Principle

Features

1. Inner air duct type structure, good air tightness, avoid cold bridge.

● The full panel is detachable, with a maintenance platform, which is convenient and simple to maintain.

● Segmented (layer) structure design, no need for ultra-high transportation, can be assembled on site to improve the quality of the whole machine.

2. The core body adopts a new structure design, which can be quickly disassembled and replaced, effectively reducing the maintenance cost in the later period.

3. The whole machine adopts PLC and touch screen intelligent control, provides a variety of interface types, and detects the ambient temperature and humidity in real time.

4. The unit reserves the energy consumption collection interface, which can collect power consumption data in real time.

5. The dew point indirect evaporation core is made of high hydrophilic polymer material and wide-pitch plate structure, and the wet bulb efficiency is as high as 95%.

6. Large-aperture three-dimensional water distribution, uniform water distribution, not easy to block, can be cleaned; flexible water spray, to prevent drift water leakage.

7. The water system adopts double descaling, sterilization and purification treatment to ensure stable operation and long life of the unit.

8. The unit has complete protection functions, and can provide alarms such as power phase loss, undervoltage, overload, differential pressure, antifreeze, and abnormal liquid level.

Application

Data centers, hospitals, schools, airports, high-speed rail, shopping malls, libraries, gymnasiums, exhibition halls, etc.

Optional Function (Non-Standard)

1. Intelligent group control function: group control, realize intelligent control of 40 devices with one belt.

2. Water softening system: It can be selected in areas with hard water, which can effectively remove calcium and magnesium ions in the water, reduce maintenance workload and prolong the life of the unit.

3. Circulating water descaling, filtration and sterilization devices: maintain the cleanliness of circulating water.

4.EC fan or inverter controller.

5. Built-in mechanical refrigeration system: Compensate for insufficient cooling capacity of natural cold source.

6. Optional cold water coil, heating coil, medium efficiency filter, electric air valve and other functional sections.

7. Lightning protection and surge protection device: avoid the interference and impact of lightning and equipment on the power grid.

Specification

| Model | AJL100 | AJL150 | AJL200 | AJL300 | AJL400 |

| Max Airflows (m³/h) | 10000 | 15000 | 20000 | 30000 | 40000 |

| Highest Wet Bulb Efficiency | 120% | 120% | 120% | 120% | 120% |

| Max Power (kW) | 7.5 | 11 | 11 | 18.5 | 30 |

| Max Residual Pressure (Pa) | 1800 | 2000 | 2000 | 2000 | 2000 |

For specific performance parameters, dimensions and use of non-standard working conditions, please contact the company's technical department.

Project Cases

![]() Power Industry Ventilation and Cooling

Power Industry Ventilation and Cooling

![]() Public Medical System Application Case 1

Public Medical System Application Case 1

![]() Public Medical System Application Case 2

Public Medical System Application Case 2

![]() Gymnasium Canteen Application Case

Gymnasium Canteen Application Case

Overview

This product integrates a number of key technologies such as indirect dew point evaporation, heat and moisture exchange of fillers, three-dimensional variable flow and uniform water distribution, real-time water quality detection and processing, and intelligent group control. Noise and other characteristics, for the application of fresh air treatment of public construction projects in dry areas, floor cold radiation cooling and other applications, it can replace mechanical refrigeration, and the energy saving effect is very obvious.

Working Principle

Features

1. Compared with mechanical refrigeration equipment, it can save energy by more than 85% under the same cooling capacity and greatly reduce operating costs.

2. The filler is made of organic polymer material, which has good flame retardant and antibacterial properties.

3. The packing adopts a new structure design, which can be quickly disassembled and replaced, effectively reducing the maintenance cost in the later period.

4. It adopts DC brushless EC fan, which has the characteristics of high reliability, high efficiency, long life, low vibration, low noise and uninterrupted operation, and can effectively prevent the intrusion of rain, snow and sand, and keep the water quality clean.

5. The whole machine adopts PLC and touch screen intelligent control, providing a variety of interface types. Real-time detection of water temperature, automatic control of fan speed.

6. The water tank is made of stainless steel, which has good rust and corrosion resistance. There is a quick access port for the water tank, which is convenient for water tank cleaning and component maintenance.

7. The dew-point indirect evaporative cooling core is made of high hydrophilic polymer material by special process, and adopts wide-pitch plate structure, which has high strength, high heat exchange efficiency, corrosion resistance and long life, and has self-cleaning function. .

8. Large aperture three-dimensional water distribution technology, uniform water distribution, not easy to block; patented structure design, more suitable for variable flow operation.

9. The mechanical strength of the box body reaches European standards; the thermal insulation panel adopts new energy-saving materials that are safe and environmentally friendly.

10. The unit has complete protection functions, providing alarm functions such as power phase loss, undervoltage, antifreeze, and abnormal liquid level.

Application

Data centers, hospitals, schools, airports, high-speed rail, shopping malls, libraries, gymnasiums, exhibition halls, etc.

Optional Function (Non-Standard)

1. Intelligent group control function: group control, realize intelligent group control with 40 devices.

2. Water softening system: It can be selected in areas with hard water quality, which can effectively remove calcium and magnesium ions in the water, reduce maintenance workload, and prolong the life of the unit.

3. Built-in board replacement and primary pump system: realize rapid on-site layout and reduce engineering volume.

4. Built-in mechanical refrigeration system: Compensate for insufficient cooling capacity of natural cold source.

5. Circulating water descaling, filtration and sterilization devices: maintain the cleanliness of circulating water.

6. Antifreeze device: avoid freezing of water in the water tank due to low ambient temperature.

7. Lightning protection and surge protection device: avoid the interference and impact of lightning and equipment on the power grid.

Specification

| Model | AGS20 (Single module) | AGS30 (Single module) | AGS40 (Single module) |

| Maximum Circulating Water Volume (m³/h) | 20 | 30 | 40 |

| Supply and Return Water Temperature Difference (℃) | 3/5/10 | 3/5/10 | 3/5/10 |

| Max Power (kW) | 7.67 | 11.43 | 14.61 |

| Max Noise (dB(A)) | 72 | 74 | 76 |

For specific performance parameters, dimensions and use of non-standard working conditions, please contact the company's technical department.

Project Cases

![]() Library Classroom Application Case

Library Classroom Application Case

![]() Exhibition Hall Application Case

Exhibition Hall Application Case

![]() Gymnasium Canteen Application Case

Gymnasium Canteen Application Case

![]() Public Medical System application case 2

Public Medical System application case 2

![]() Data Room Ventilation and Cooling

Data Room Ventilation and Cooling

Features

1. Using unitary tank, compact structure with high strength.

2. Using double inlet forward centrifugal fan with large airflow, big air pressure and long drive distance.

3. The fan volute is made of plastic one-step injection molding with high efficiency, low noise, light weight and excellent rust resistance.

4. Using high efficiency and energy-saving motor, it can be running longtime even in high humidity.

5. Air inlet by plastic mesh, with little resistance, water and air can contact with each other completely to have high evaporation efficiency.

6. Using high efficiency evaporative pads, good cooling effects and easy to clean.

Application

Tall spaces, large factories (automobile factories, machinery factories, logistics and warehousing), public buildings (gymnasiums, libraries, high-speed rail stations, airports), commercial buildings (commercial plazas, large supermarkets, farmers markets).

Specification

| Model/Specs | AZL25-LX31F AZL25-LS31F AZL25-LC31F | AZL30-LX31F AZL30-LS31F AZL30-LC31F | AZL35-LX31F AZL35-LS31F AZL35-LC31F | AZL40-LX31F AZL40-LS31F AZL40-LC31F | AZL50-LX31F AZL50-LS31F AZL50-LC31F |

| X-down discharge, S-up discharge, C-side discharge | |||||

| Electrial Source | 380-415/50-60(V/Hz) 3-phase | 380-415/50-60(V/Hz) 3-phase | 380-415/50-60(V/Hz) 3-phase | 380-415/50-60(V/Hz) 3-phase | 380-415/50-60(V/Hz) 3-phase |

| Power (kW) | 3 | 4 | 5.5 | 7.5 | 15 |

| Rated Current (A) | 6.8 | 8.8 | 11.6 | 15.9 | 30.5 |

| Airflows (m³/h) | 25000 | 30000 | 35000 | 40000 | 50000 |

| Fan Type | Centrifugal | Centrifugal | Centrifugal | Centrifugal | Centrifugal |

| Fan Speed | 3-phase, 1-speed | 3-phase, 1-speed | 3-phase, 1-speed | 3-phase, 1-speed | 3-phase, 1-speed |

| Pressure (Pa) | 240 | 280 | 300 | 300 | 500 |

| Vent Size (L*W) (mm) | 707*648 (down) 772*707 (up/side) | 707*648 (down) 772*707 (up/side) | 803*718 (down) 843*747 (up/side) | 803*718 (down) 843*747 (up/side) | 803*718 (down) 843*747 (up/side) |

| Noise (dB(A)) | ≤74 | ≤76 | ≤81 | ≤83 | ≤85 |

| Dimension (L*W*H) (mm) | 1385*1515*1400 (down) 1385*1515*1460 (up) 1450*1515*1400 (side) | 1385*1515*1400 (down) 1385*1515*1460 (up) 1450*1515*1400 (side) | 1600*1750*1550 (down) 1600*1750*1585 (up) 1635*1750*1550 (side) | 1600*1750*1550 (down) 1600*1750*1585 (up) 1635*1750*1550 (side) | 1600*1830*1705 (down) 1600*1830*1740 (up) 1635*1830*1705 (side) |

| Pad Size (L*W*H) (mm) | 1100*520*100 (down/up/side) 1100*465*120 (down/up/side) | 1100*520*100 (down/up/side) 1100*465*120 (down/up/side) | 1237*634*100 (down/up/side) 1237*573*120 (down/up/side) | 1237*634*100 (down/up/side) 1237*573*120 (down/up/side) | 1363*670*100 (down/up/side) 1363*568*120 (down/up/side) |

| Aluminum Alloy Shell | Optional | Optional | Optional | Optional | Optional |

| Net Weight (±3Kg) | 315 | 320 | 490 | 505 | 675 |

| Operatlon Weight (kg) | 365 | 370 | 550 | 565 | 765 |

| Controller | Button+Knob Switch | Button+Knob Switch | Button+Knob Switch | Button+Knob Switch | Button+Knob Switch |

| QTY/Full (40HQ) | 8 | 8 | 7 | 7 | 7 |

Note: The actual air volume is related to the outlet static pressure (air duct resistance). For details, please consult the company's technical department.

Project Cases

![]() Food & Beverage Processing Industry Ventilation and Cooling

Food & Beverage Processing Industry Ventilation and Cooling

![]() Automobile, Auto Parts Industry Case Display

Automobile, Auto Parts Industry Case Display

![]() Shoe and Clothing Industry Case Show

Shoe and Clothing Industry Case Show

![]() Packaging & Printing Industry Ventilation and Cooling Cases

Packaging & Printing Industry Ventilation and Cooling Cases

![]() Construction, Chemical Industry and Plastic Processing Industry Ventilation and Cooling

Construction, Chemical Industry and Plastic Processing Industry Ventilation and Cooling

![]() Electromechanical & Machinery Manufacturing Industry Ventilation and Cooling

Electromechanical & Machinery Manufacturing Industry Ventilation and Cooling

![]() Airport Station & Subway Ventilation and Cooling

Airport Station & Subway Ventilation and Cooling

![]() Gymnasiums, Exhibition Halls and Libraries Ventilation and Cooling

Gymnasiums, Exhibition Halls and Libraries Ventilation and Cooling

![]() Supermarket & Market Ventilation and Cooling

Supermarket & Market Ventilation and Cooling

![]() Exhibition Hall & Restaurant Ventilation and Cooling

Exhibition Hall & Restaurant Ventilation and Cooling

Overview

On the basis of integrating direct evaporative cooling technology and external cooling indirect evaporative cooling technology, this product can add other functions such as medium and high efficiency filtration, mechanical refrigeration section, surface cooling section, heating section, muffler section and humidification section according to actual engineering needs. It adopts modular design and has the characteristics of high efficiency and energy saving, stable operation, anti-freezing and low noise. It can be used for fresh air cooling in public construction projects and industrial workshops in dry areas, and can replace mechanical refrigeration. The energy saving effect is very obvious. It is also suitable for energy-saving cooling in various data centers, computer rooms and power distribution rooms.

Working Principle

Features

1. The direct evaporative cooling technology is adopted, and the outdoor dry air can be fully utilized to reduce the energy consumption of the fresh fan operation, and the energy saving effect is outstanding.

2. The unit adopts anti-cold bridge aluminum alloy frame, seamless socket splicing panel, high-pressure polyurethane insulation board, which has good thermal insulation performance and sealing performance.

3. The filler made of plant long fiber material or polymer material has a flame retardant grade of B1, a water absorption efficiency of up to 250%, an evaporation efficiency of up to 95%, long life, no peculiar smell, and no harmful substances such as phenol. Comply with environmental ROHS and REACH certification requirements.

4. The unit has a built-in water tank, which can be recycled. It adopts advanced water distribution design, low wind speed on the windward side, no floating water, long water exchange cycle, and reduces water consumption and pump energy consumption.

5. The unit can be equipped with primary, medium and high-efficiency filter screens, and the filter grades are optional. The function section is set reasonably, and the heating section, mechanical refrigeration section, etc. can be selected according to the actual use requirements.

6. The ratio of mechanical refrigeration system can be adjusted according to actual requirements, and the energy efficiency ratio is higher.

7. Intelligent control, using a central controller, can realize automatic adjustment of air volume, temperature and humidity control, fault alarm, and group control of multiple units.

Application

Data centers, hospitals, schools, airports, high-speed rail, shopping malls, libraries, gymnasiums, exhibition halls, etc.

Optional Function (Non-Standard)

1. Intelligent group control function: group control, realize intelligent control of 40 devices with one belt.

2. Water softening system: It can be selected in areas with hard water, which can effectively remove calcium and magnesium ions in the water, reduce maintenance workload and prolong the life of the unit.

3. Circulating water descaling, filtration and sterilization devices: maintain the cleanliness of circulating water.

4.EC fan or inverter controller.

5. Built-in mechanical refrigeration system: Compensate for insufficient cooling capacity of natural cold source.

6. Optional cold water coil, heating coil, medium efficiency filter, electric air valve and other functional sections.

Specification

| Model | AZK05 | AZK10 | AZK15 | AZK20 | AZK30 | AZK50 | AZK80 | AZK10 |

| Max Airflows (m³/h) | 5000 | 1000 | 15000 | 20000 | 30000 | 50000 | 80000 | 100000 |

| Max Residual Pressure (Pa) | 400 | 15000 | 600 | 800 | 1000 | 1000 | 1000 | 1000 |

| Max Power (kW) | 7.5 | 11 | 15 | 22 | 30 | 45 | 75 | 90 |

| Number of Coil (R) | 4/6/8/10 | 4/6/8/10 | 4/6/8/10 | 4/6/8/10 | 4/6/8/10 | 4/6/8/10 | 4/6/8/10 | 4/6/8/10 |

Max Cooling Pad Thickness (mm) | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| Fan Type | Centrifugal | Centrifugal | Centrifugal | Centrifugal | Centrifugal | Centrifugal | Centrifugal | Centrifugal |

For specific performance parameters, dimensions and use of non-standard working conditions, please contact the company's technical department.

Project Cases

![]() Public Medical System Application Case 1

Public Medical System Application Case 1

![]() Public Medical System Application Case 2

Public Medical System Application Case 2

![]() Library Classroom Application Case

Library Classroom Application Case

![]() Exhibition Hall Application Case

Exhibition Hall Application Case

![]() Gymnasium Canteen Application Case

Gymnasium Canteen Application Case

![]() High-speed Railway Station Cooling

High-speed Railway Station Cooling

![]() Data Room Ventilation and Cooling

Data Room Ventilation and Cooling

Features

1. The shell is made of high-strength weather-resistant engineering plastics, anti-aging, anti-UV, anti-corrosion and no deformation, warranty for more than ten years.

2. New side panel, lower hook louver to prevent water drift and water leakage.

3. Equipped with a molded dust filter, easy to disassemble and maintain.

4. The Evaporative pads are made of raw wood pulp paper fiber composite, which is easy to clean and has a significant cooling effect.

5. Using high-quality fully enclosed aluminum shell motor, good heat dissipation, high insulation protection level, waterproof and moisture-proof.

6. Adopt automatic control water system, open water distributor, make the water flow even and smooth, not easy to block.

7. Large air supply, low noise, flat curve, high efficiency and wide working range.

8. Low water level high foot pump, flame retardant shell, built-in thermal protection switch, safe and reliable.

9. There are three types of air outlet, top, down and side to choose from.

Application

Small and medium-sized industrial plants, semi-open venues, outdoor exhibition venues, agricultural and animal husbandry bases, etc.

Specification

| Model/Specs | AZL25-ZX32C AZL25-ZS32C AZL25-ZC32C | AZL25-ZX30C AZL25-ZS30C AZL25-ZC30C | AZL30-ZX32C AZL30-ZS32C AZL30-ZC32C | AZL30-ZX30C AZL30-ZS30C AZL30-ZC30C |

| X-down discharge, S-up discharge, C-side discharge | ||||

| Electrial Source | 380-415/50-60(V/Hz) 3-phase | 380-415/50-60(V/Hz) 3-phase | 380-415/50-60(V/Hz) 3-phase | 380-415/50-60(V/Hz) 3-phase |

| Power (kW) | 2.2/0.75 | 2.2 | 3.0/1.0 | 3.0 |

| Rated Current (A) | 5.4/0.75 | 5.4 | 7.1/3.5 | 7.1 |

| Airflows (m³/h) | 25000/16000 | 25000 | 30000/20000 | 30000 |

| Fan Type | Axial | Axial | Axial | Axial |

| Fan Speed | 3-phase, 2-speed | Multi-speed, Inverter | 3-phase, 2-speed | Multi-speed, Inverter |

| Pressure (Pa) | 300/136 | 306 | 320/160 | 320 |

| Vent Size (L*W) (mm) | 765*765 | 765*765 | 765*765 | 765*765 |

| Noise (dB(A)) | ≤78 | ≤78 | ≤80 | ≤80 |

| Dimension (L*W*H) (mm) | 1350*1350*1310 (down) 1350*1350*1426 (up) 1350*1350*1310 (side) | 1350*1350*1310 (down) 1350*1350*1426 (up) 1350*1350*1310 (side) | 1350*1350*1310 (down) 1350*1350*1426 (up) 1350*1350*1310 (side) | 1350*1350*1310 (down) 1350*1350*1426 (up) 1350*1350*1310 (side) |

| Pad Size (L*W*H) (mm) | 970*881*100 | 970*881*100 | 970*881*100 | 970*881*100 |

| Net Weight (±3Kg) | 120 (down) 147 (up) 156 (side) | 120 (down) 147 (up) 156 (side) | 125 (down) 152 (up) 161 (side) | 125 (down) 152 (up) 161 (side) |

| Operatlon Weight (kg) | 175 (down) 202 (up) 211 (side) | 175 (down) 202 (up) 211 (side) | 180 (down) 207 (up) 216 (side) | 180 (down) 207 (up) 216 (side) |

| Controller | LED Control | LED Control | LED Control | LED Control |

| Pre-dust Fi;ter | Optional | Optional | Optional | Optional |

| Pre-dcooling | Optional | Optional | Optional | Optional |

| Group-control | Optional | Optional | Optional | Optional |

| Tem&hum Control | Optional | Optional | Optional | Optional |

| QTY/Full (40HQ) | 9 | 9 | 9 | 9 |

| QTY/SKD (40HQ) | 45 (down)/39 (up)/42 (side) | 45 (down)/39 (up)/42 (side) | 45 (down)/39 (up)/42 (side) | 45 (down)/39 (up)/42 (side) |

Note: The actual airflow is related to the outlet pressure (air duct resistance). Please consult the company's technical department for details.

Project Cases

![]() Food & Beverage Processing Industry Ventilation and Cooling

Food & Beverage Processing Industry Ventilation and Cooling

![]() Automobile, Auto Parts Industry Case Display

Automobile, Auto Parts Industry Case Display

![]() Shoe and Clothing Industry Case Show

Shoe and Clothing Industry Case Show

![]() Packaging & Printing Industry Ventilation and Cooling Cases

Packaging & Printing Industry Ventilation and Cooling Cases

![]() Construction, Chemical Industry and Plastic Processing Industry Ventilation and Cooling

Construction, Chemical Industry and Plastic Processing Industry Ventilation and Cooling

![]() Electromechanical & Machinery Manufacturing Industry Ventilation and Cooling

Electromechanical & Machinery Manufacturing Industry Ventilation and Cooling

![]() Airport Station & Subway Ventilation and Cooling

Airport Station & Subway Ventilation and Cooling

![]() Gymnasiums, Exhibition Halls and Libraries Ventilation and Cooling

Gymnasiums, Exhibition Halls and Libraries Ventilation and Cooling

![]() Club & Outdoor Activity Space Ventilation and Cooling

Club & Outdoor Activity Space Ventilation and Cooling

![]() Supermarket & Market Ventilation and Cooling

Supermarket & Market Ventilation and Cooling

![]() Exhibition Hall & Restaurant Ventilation and Cooling

Exhibition Hall & Restaurant Ventilation and Cooling

![]() Data Room Ventilation and Cooling

Data Room Ventilation and Cooling

Features

1.Equipped with brushless DC motor, the cooler runs smoothly with low noise. Motor with light-weight, less noise, no excitation sound.

2.Operate on both 50HZ/60HZ. The running voltage is among 200-264V.

3.Motor with high efficiency, running cost is saved 20% for the same running conditions.

4.For centrifugal unit, with motor direct-connected, there is less running parts,easy maintenance.

5. Using intelligent LCD controller, the working status and fault display of the equipment are clear at a glance.

6. Constant power electronic control, automatically sense the resistance to adjust the air pressure and air volume to ensure the air supply volume and air supply distance.

7. The professionally designed forward-leaning multi-blade centrifugal fan is adopted, with high static pressure at the outlet and long air supply distance.

8. The volute and impeller are made of new composite materials, which are light in weight, corrosion-resistant, anti-aging and have good vibration-absorbing effect.

9. There are two ways of air outlet, upper and lower, with stable operation and low noise, especially suitable for commercial places.

10. With air damper to avoid hot air outlet in winter.

Application

Commercial places, industrial plants, communication equipment rooms, home/office places, etc. that have noise requirements.

Specification

| Model/Specs | AZL18-ZX10EZ AZL18-ZS10EZ AZL18-ZC10EZ | AZL18-LX10CZ AZL18-LS10CZ |

| X-down discharge, S-up discharge, C-side discharge | ||

| Electrial Source | 220~240/50~60 | 220~240/50~60 |

| Power (kW) | 0.65 | 1.5 |

| Motor | DC (220V 3-phase) | DC (220V 3-phase) |

| Rated Current (A) | 3 | 7.5 |

| Airflows (m³/h) | 18000 | 18000 |

| Fan Type | Axial | Axial |

| Fan Speed | Multi-speed, Inverter | Multi-speed, Inverter |

| Pressure (Pa) | 170 | 183 |

| Vent Size (L*W) (mm) | 650*650 (down) 647*647 (up) 650*650 (down) | 650*650 |

| Noise (dB(A)) | ≤67 | ≤65 |

| Dimension (L*W*H) (mm) | 1150*1150*950 (down) 1150*1150*982 (up) 1210*1150*950 (side) | 1150*1150*950 (down) 1150*1150*982 (up) |

| Pad Size (L*W*H) (mm) | 620*825*100 | 620*825*72 620*825*100 |

| Net Weight (±3Kg) | 67 (down) 73 (up) 87 (side) | 79 |

| Operatlon Weight (kg) | 97 (down) 103 (up) 117 (side) | 107 |

| Controller | LED Control | LED Control |

| Pre-dust Fi;ter | Optional | Optional |

| Pre-dcooling | Optional | Optional |

| Group-control | Optional | Optional |

| Tem&hum Control | Optional | Optional |

| QTY/Full (40HQ) | 40 | 40 |

| QTY/SKD (40HQ) | 70 (down)/65 (up)/40 (side) | 45 |

Note: The actual airflow is related to the outlet static pressure (air duct resistance). For details, please consult the company's technical department.

Project Cases

![]() Food & Beverage Processing Industry Ventilation and Cooling

Food & Beverage Processing Industry Ventilation and Cooling

![]() Automobile, Auto Parts Industry Case Display

Automobile, Auto Parts Industry Case Display

![]() Shoe and Clothing Industry Case Show

Shoe and Clothing Industry Case Show

![]() Packaging & Printing Industry Ventilation and Cooling Cases

Packaging & Printing Industry Ventilation and Cooling Cases

![]() Construction, Chemical Industry and Plastic Processing Industry Ventilation and Cooling

Construction, Chemical Industry and Plastic Processing Industry Ventilation and Cooling

![]() Electromechanical & Machinery Manufacturing Industry Ventilation and Cooling

Electromechanical & Machinery Manufacturing Industry Ventilation and Cooling

![]() Airport Station & Subway Ventilation and Cooling

Airport Station & Subway Ventilation and Cooling

![]() Gymnasiums, Exhibition Halls and Libraries Ventilation and Cooling

Gymnasiums, Exhibition Halls and Libraries Ventilation and Cooling

![]() Club & Outdoor Activity Space Ventilation and Cooling

Club & Outdoor Activity Space Ventilation and Cooling

![]() Supermarket & Market Ventilation and Cooling

Supermarket & Market Ventilation and Cooling

![]() Office & Home & Dormitory Ventilation and Cooling

Office & Home & Dormitory Ventilation and Cooling

![]() Exhibition Hall & Restaurant Ventilation and Cooling

Exhibition Hall & Restaurant Ventilation and Cooling

![]() Data Room Ventilation and Cooling

Data Room Ventilation and Cooling

Features

1. Reasonable design with strong structure.

2. Slant water tank with drain valve in lowest place, while drainage, water-flow can wash tank.

3. Integrated water distributor with only one built-in pipe -no risk for water leakage.

4.The installation position of the drain valve adopts a sinking design, which is conducive to cleaning and discharging of dirt.

5. The tank slope design, the drainage is extremely clean and smooth.

6. With air damper to avoid hot air outlet in winter.

7. Easy installation filter, which is easy to clean.

8. Using LCD or standard controller, easy to operate.

9. Materials for casing are anti-UV, anti-corrosion, anti-aging, and no deformation.

10. Fan impeller is special designed to allow large airflow but lower noise.

11. Motor applied is moistureproof, waterproof with tiny temperature rise.

12. Using high efficient cooling pads with large evaporation capacity, good cooling efficiency and easy to clean.

13. With top, down and side discharge, to meet a variety of installation environments.

Application

Small and medium-sized industrial plants, commercial places, communication rooms, semi-open places, outdoor exhibition places, etc.

Specification

| Model/Specs | AZL18-ZX10E AZL18-ZS10E AZL18-ZC10E | AZL18-ZX10G AZL18-ZS10G AZL18-ZC10G | AZL18-ZX32E AZL18-ZS32E AZL18-ZC32E |

| X-down discharge, S-up discharge, C-side discharge | |||

| Electrial Source | 110/60 220/50(V/Hz) 1-phase | 110/60 220/50(V/Hz) 1-phase | 110/60 220/50(V/Hz) 3-phase |

| Power (kW) | 1.1 | 1.1 | 1.1 |

| Rated Current (A) | 5.6 | 4.8 | 1.1/0.37 |

| Airflows (m³/h) | 18000 | 18000 | 18000 |

| Fan Type | Axial | Axial | Axial |

| Fan Speed | Multi-speed, Silicon Control | Multi-speed, Inverter | 3-phase, 2-speed |

| Pressure (Pa) | 170 | 170 | 170/63 |

| Vent Size (L*W) (mm) | 650*650 (down) 650*650 (up) 647*647 (side) | 650*650 (down) 650*650 (up) 647*647 (side) | 650*650 (down) 650*650 (up) 647*647 (side) |

| Noise (dB(A)) | ≤76 | ≤76 | ≤76 |

| Dimension (L*W*H) (mm) | 1150*1150*950 (down) 1150*1150*982 (up) 1210*1150*950 (side) | 1150*1150*950 (down) 1150*1150*982 (up) 1210*1150*950 (side) | 1150*1150*950 (down) 1150*1150*982 (up) 1210*1150*950 (side) |

| Pad Size (L*W*H) (mm) | 620*825*100 | 620*825*100 | 620*825*100 |

| Net Weight (±3Kg) | 80 (down) 86 (up) 100 (side) | 80 (down) 86 (up) 100 (side) | 80 (down) 86 (up) 100 (side) |

| Operatlon Weight (kg) | 110 (down) 116 (up) 130 (side) | 110 (down) 116 (up) 130 (side) | 110 (down) 116 (up) 130 (side) |

| Controller | LED Control | LED Control | LED Control |

| Pre-dust Fi;ter | Optional | Optional | Optional |

| Pre-dcooling | Optional | Optional | Optional |

| Group-control | Optional | Optional | Optional |

| Tem&hum Control | Optional | Optional | Optional |

| QTY/Full (40HQ) | 40 | 40 | 40 |

| QTY/SKD (40HQ) | 70 (down)/65 (up)/40 (side) | 70 (down)/65 (up)/40 (side) | 70 (down)/65 (up)/40 (side) |

Note: The actual airflow is related to the outlet static pressure (air duct resistance). For details, please consult the company's technical department.

Project Cases

![]() Food & Beverage Processing Industry Ventilation and Cooling

Food & Beverage Processing Industry Ventilation and Cooling

![]() Automobile, Auto Parts Industry Case Display

Automobile, Auto Parts Industry Case Display

![]() Shoe and Clothing Industry Case Show

Shoe and Clothing Industry Case Show

![]() Packaging & Printing Industry Ventilation and Cooling Cases

Packaging & Printing Industry Ventilation and Cooling Cases

![]() Construction, Chemical Industry and Plastic Processing Industry Ventilation and Cooling

Construction, Chemical Industry and Plastic Processing Industry Ventilation and Cooling

![]() Electromechanical & Machinery Manufacturing Industry Ventilation and Cooling

Electromechanical & Machinery Manufacturing Industry Ventilation and Cooling

![]() Airport Station & Subway Ventilation and Cooling

Airport Station & Subway Ventilation and Cooling

![]() Gymnasiums, Exhibition Halls and Libraries Ventilation and Cooling

Gymnasiums, Exhibition Halls and Libraries Ventilation and Cooling

![]() Club & Outdoor Activity Space Ventilation and Cooling

Club & Outdoor Activity Space Ventilation and Cooling

![]() Supermarket & Market Ventilation and Cooling

Supermarket & Market Ventilation and Cooling

![]() Office & Home & Dormitory Ventilation and Cooling

Office & Home & Dormitory Ventilation and Cooling

![]() Exhibition Hall & Restaurant Ventilation and Cooling

Exhibition Hall & Restaurant Ventilation and Cooling

![]() Data Room Ventilation and Cooling

Data Room Ventilation and Cooling

Features

1. Fan speeds : 1-phase variable-speed, 3-phase 1-spped or 2-speed.

2. Different air discharges (top, down or side) meet different installation requirements.

3. Using LCD or standard controller, easy to operate.

4. Materials for casing are anti-UV, anti-corrosion, anti-aging, and no deformation.

5. Fan impeller is special designed to allow large airflow but lower noise.

6. Motor applied with moisture proof, waterproof and tiny temperature rise.

7. Using automatic control water system and open type water distributor, water can flow smoothly and distributor is not easy to block.

8. Using high efficient evaporative pads with large evaporation capacity, good cooling efficiency and easy to clean.

Application

Small and medium-sized industrial plants, commercial places, communication rooms, semi-open places, outdoor exhibition places, etc.

Specification

| Model/Specs | AZL18-ZX10B AZL18-ZS10B AZL18-ZC10B | AZL18-ZX31B AZL18-ZS31B | AZL18-ZX32B AZL18-ZS32B |

| X-down discharge, S-up discharge, C-side discharge | |||

| Electrial Source | 110/60 220/50(V/Hz) 1-phase | 110/60 220/50(V/Hz) 3-phase | 110/60 220/50(V/Hz) 3-phase |

| Power (kW) | 1.1 | 1.1 | 1.1/0.37 |

| Rated Current (A) | 5.6 | 2.6 | 2.0/0.85 |

| Airflows (m³/h) | 18000 | 18000 | 18000 |

| Fan Type | Axial | Axial | Axial |

| Fan Speed | Multi-speed, Silicon Control | 3-phase, 1-speed | 3-phase, 2-speed |

| Pressure (Pa) | 170 | 170 | 170/88 |

| Vent Size (L*W) (mm) | 655*655 (down) 655*655 (up) 676*676 (side) | 655*655 | 655*655 |

| Noise (dB(A)) | ≤76 | ≤76 | ≤76 |

| Dimension (L*W*H) (mm) | 1170*1170*960 (down) 1170*1170*1052 (up) 1170*1250*960 (side) | 1170*1170*960 (down) 1170*1170*1052 (up) | 1170*1170*960 (down) 1170*1170*1052 (up) |

| Pad Size (L*W*H) (mm) | 675*855*100 | 675*855*100 | 675*855*100 |

| Net Weight (±3Kg) | 124 (down) 90 (up) 95 (side) | 84 (down) 90 (up) | 84 (down) 90 (up) |

| Operatlon Weight (kg) | 124 (down) 130 (up) 135 (side) | 124 (down) 130 (up) | 124 (down) 130 (up) |

| Controller | LED Control | LED Control | LED Control |

| Pre-dust Fi;ter | Optional | Optional | Optional |

| Pre-dcooling | Optional | Optional | Optional |

| Group-control | Optional | Optional | Optional |

| Tem&hum Control | Optional | Optional | Optional |

| QTY/Full (40HQ) | 40 (down/up)36 (side) | 40 | 40 |

| QTY/SKD (40HQ) | 70 (down)/55 (up)/64 (side) | 70 (down)/55 (up)/64 (side) | 70 (down)/55 (up)/64 (side) |