Your current location:Home > Project > Liquid Desiccant Air Conditioner

Lithium Battery Industry

Industry Overview

With the rapid development of new energy technology, the demand for process air conditioners is increasing, and the requirements for process and energy saving are also getting higher and higher. For lithium battery production workshops, laser welding rooms, assembly rooms, etc., the temperature is required to be 25±2°C, and the relative humidity is required to be ≤30%.

The Freezing Dehumidifier method uses low-temperature cold water or refrigerant to contact the air through the surface cooler coil, so that the air is cooled to the dew point and then dehumidified. The air temperature after freezing and dehumidifying is too low, and the dehumidified air needs to be reheated to reach the air supply state point. In the reheating process, there is a problem that the heat and cold are offset and the energy consumption is too large.

Another common Desiccant Wheel is to use impregnated microporous moisture absorbent material to absorb moisture in the air to dry the air, and use high-temperature air in the regeneration area to take away the moisture for regeneration. Due to the high regeneration temperature of rotary dehumidification, the air needs to be cooled again after dehumidification to reach the air supply state point. The cooling process after dehumidifying requires a large amount of cooling, and there is a problem of huge energy consumption.

In the solution dehumidifying system, the solution is used as a hygroscopic material, and the difference between the vapor pressure of the solution surface and the vapor pressure of the air to be treated is used as the driving force for mass transfer to dehumidify the air. The solution dehumidifying system has the advantages of independent control of air temperature and humidity, high energy efficiency, avoiding the process of reheating or recooling the air after dehumidifying, and high air supply cleanliness. It is an important alternative to the above two common dehumidifying systems. It is widely used in battery factories or energy-saving renovation of existing dehumidifying systems.

Project Introduction

A lithium battery production plant is located in a city in the south, which is hot in summer and cold in winter. In the production process of lithium battery cathode, graphite powder, mixed binder and other solvents need to be prepared into graphite slurry, and then applied to the surface of aluminum foil. The workshop requires a temperature of 24±3℃ and a relative humidity of ≤40% (absolute humidity between 6g/kg and 9g/kg).

There is a 30000m³/h Liquid Type Central Air Conditioner installed, with a fresh air ratio of 25%. The air treatment process of the Liquid Desiccant Air conditioner system as follow:

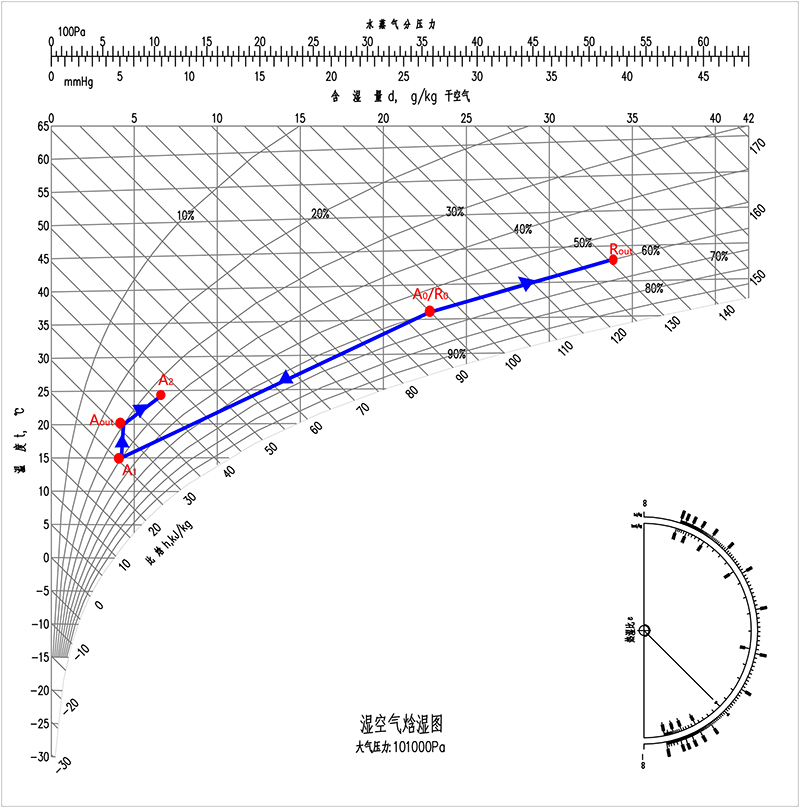

In cooling and dehumidifying section, fresh air A0 (36℃, 60%) is cooled and dehumidified to A1 (15℃, 40%). Fresh air mixed with the indoor return air A2 (24℃, 35%) to Supply air Aout (20℃, 30%).

In the regenerating section, the temperature of the solution heated by the condenser, and the moisture is released to the fresh air from the outdoor state point of R0 (36°C, 60%) to achieve regeneration. After moisture absorption, the state point is ROUT ( 43°C, 60%) of the regeneration air is exhausted.

In this system, the evaporator of the heat pump provides the cooling capacity required for dehumidification of the solution, the condenser of the heat pump provides the heat required for the regeneration of the solution, and the processed air directly reaches the point of supply air. No need re-heat and re-cool power consumption.