Your current location:Home > Project > Industrial Cooling

Power Industry Ventilation and Cooling

Industry Overview

With the cost reduction and efficiency increase, energy conservation and emission reduction work in all areas in full swing, energy conservation and cost reduction in power places are also increasingly valued. The high-voltage frequency conversion room, distribution room, control room and other high heating areas of power plants, as well as the power control room of high energy consuming production enterprises, almost all need refrigeration throughout the year. If mechanical air conditioning is used to cool down, it can indeed meet the requirements, but the power consumption is large and the maintenance cost is high. However, if forced ventilation equipment such as fans and ventilators are used, it is difficult to ensure the indoor temperature conditions during the high temperature period in summer. Therefore, it is considered to be a very suitable choice to make full use of natural cold sources and adopt evaporative cooling system, which can not only meet the requirements of indoor temperature and humidity conditions, but also ensure a certain number of air exchange rate of indoor air, avoiding problems such as high temperature, static electricity, odor and so on.

Advantages of Aolan Energy Saving Cooling Solutions

Aolan provides a variety of options for evaporative cooling solutions and evaporative cooling composite mechanical refrigeration solutions for power conversion rooms, power distribution rooms and other places.

1. Evaporative cooling solution: Aolan dew point indirect evaporative cooling air conditioning unit or direct evaporative combined air conditioning unit is adopted. Outdoor fresh air is sent indoors after filtration and evaporative cooling, and is discharged outdoors after absorbing indoor heat. In the middle and north of China, it can be used all year round. The power consumption is only 15% - 40% of the power consumption of the mechanical air-conditioning system, and the equipment investment cost is about 40% - 70% of the mechanical air-conditioning system. The system investment is small, the operation cost is low, and it meets the double carbon goal.

2. Evaporative cooling + mechanical refrigeration solution: adopt AOLAN evaporative cooling air conditioning unit + linkage control auxiliary mechanical refrigeration air conditioning unit. In winter and transition seasons, outdoor fresh air is sent indoors after filtration and evaporative cooling, and then discharged outdoors after absorbing indoor heat. In the weather with abnormal high temperature and humidity, the mechanical refrigeration air conditioning unit is controlled in linkage, and the indoor air is turned into internal circulation, which is forced to cool down by mechanical refrigeration to meet the requirements. It is applicable in the central and southern regions of China. The annual power consumption of the system is about 30% - 60% of that of the mechanical air conditioning system, which not only saves energy and reduces consumption, but also reduces the maintenance workload of mechanical air conditioning.

Project Introduction

1. Evaporative cooling solution: AOLAN direct evaporation air conditioning unit is used as the cooling equipment in the high-voltage converter room of a power plant in Inner Mongolia. In winter, outdoor fresh air is filtered and sent to each converter room, absorbing indoor heat and then discharged outdoors. In summer and transition seasons, outdoor fresh air is filtered, evaporated and cooled, and then sent to each frequency converter room to absorb indoor heat and then discharged outdoors. A total of 5 units AOLAN evaporative cooling combined air conditioning units are designed and selected for this project, and the total fresh airflow of the equipment arrive 190000m ³/ h。

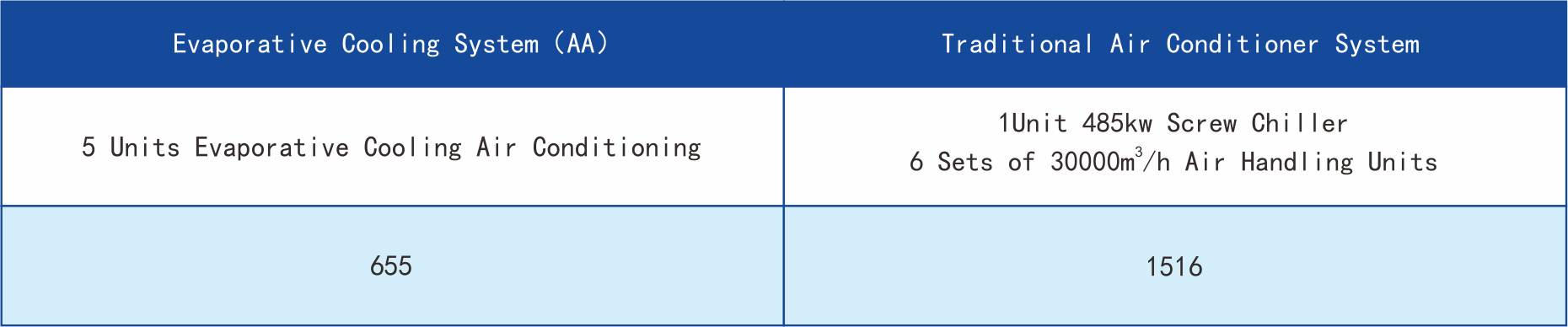

Data analysis and comparison:the total power consumption of the equipment in the whole year: kW.h/㎡

The total annual power consumption of the evaporative cooling system in this project is 655kW.h/㎡, which saves 56.8% of the annual energy consumption compared to traditional air conditioners.

2. Evaporative cooling solution: Aolan dew point indirect evaporative air-conditioning unit is used as the cooling equipment for the centralized control room of a power plant in the west. In winter, the outdoor fresh air is filtered and sent indoors, absorbs the indoor heat and then discharges outdoors. In summer and transitional seasons, the outdoor fresh air is filtered and cooled by indirect dew point evaporative cooling and sent into the room, absorbs the indoor heat and then discharges outside. A total of 6 Aolan dew point indirect evaporative cooling air-conditioning units are designed and selected for this project, and the total supply airflow of the equipment is 90000m³/h.

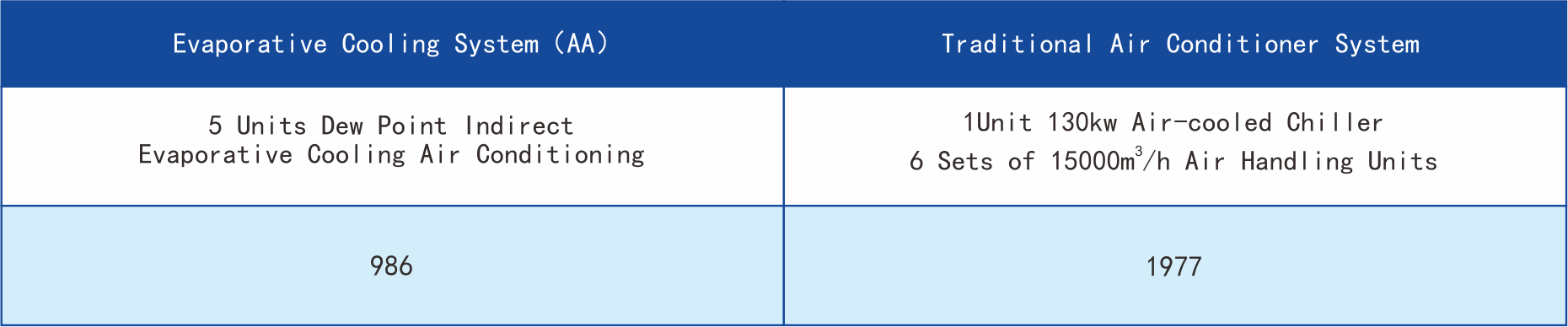

Data analysis and comparison: the total power consumption of the equipment in the whole year: kW.h/㎡

The total annual power consumption of the evaporative cooling system in this project is 986kW.h/㎡, which saves 50% of the annual energy consumption compared to traditional mechanical air conditioners.

3. Evaporative cooling composite mechanical refrigeration solution: Aolan evaporative composite mechanical refrigeration and air-conditioning unit is used as the cooling equipment for the power distribution room of a power plant in Wuhan. In winter, the outdoor fresh air is filtered and sent to each inverter room, absorbs indoor heat and then discharges outdoors. In the transition season, the outdoor fresh air is filtered, cooled by evaporative cooling and sent to each inverter room, and then discharged to the outdoor after absorbing indoor heat. In the abnormal situation of high temperature and high humidity in summer, start the mechanical refrigeration. In the case of ensuring that the indoor requirements are met, the energy-saving operation is maximized. A total of 9 Aolan evaporative cooling air-conditioning units and 9 auxiliary mechanical refrigeration chillers are designed and selected for this project, with a designed maximum total air volume of 240,000m3/h.

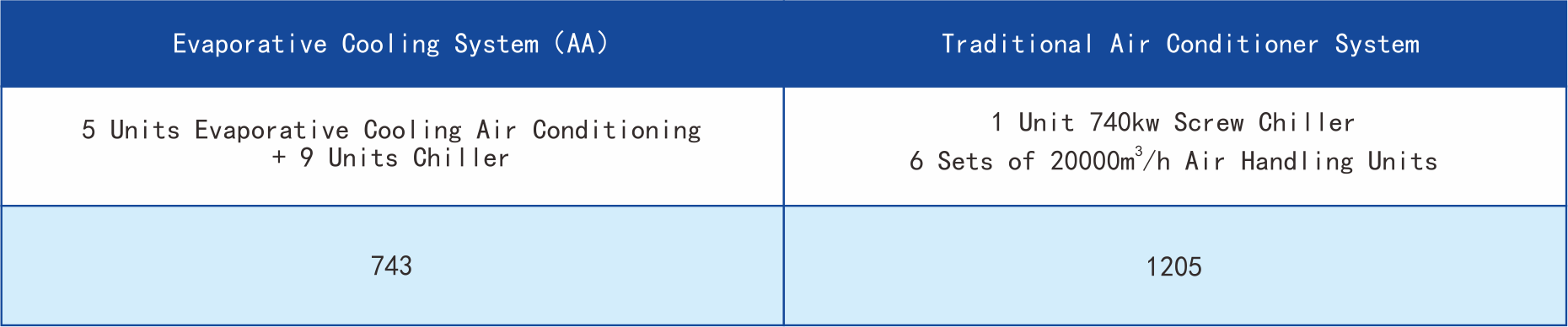

Data analysis and comparison: the total power consumption of the equipment in the whole year: kW.h/㎡

The total annual power consumption of the evaporative cooling system in this project is 743kW.h/㎡, which saves 38.5% of the annual energy consumption compared to traditional mechanical air conditioners.