Your current location:Home > Products > Evaporative Cooling High Temperature Chiller

Overview

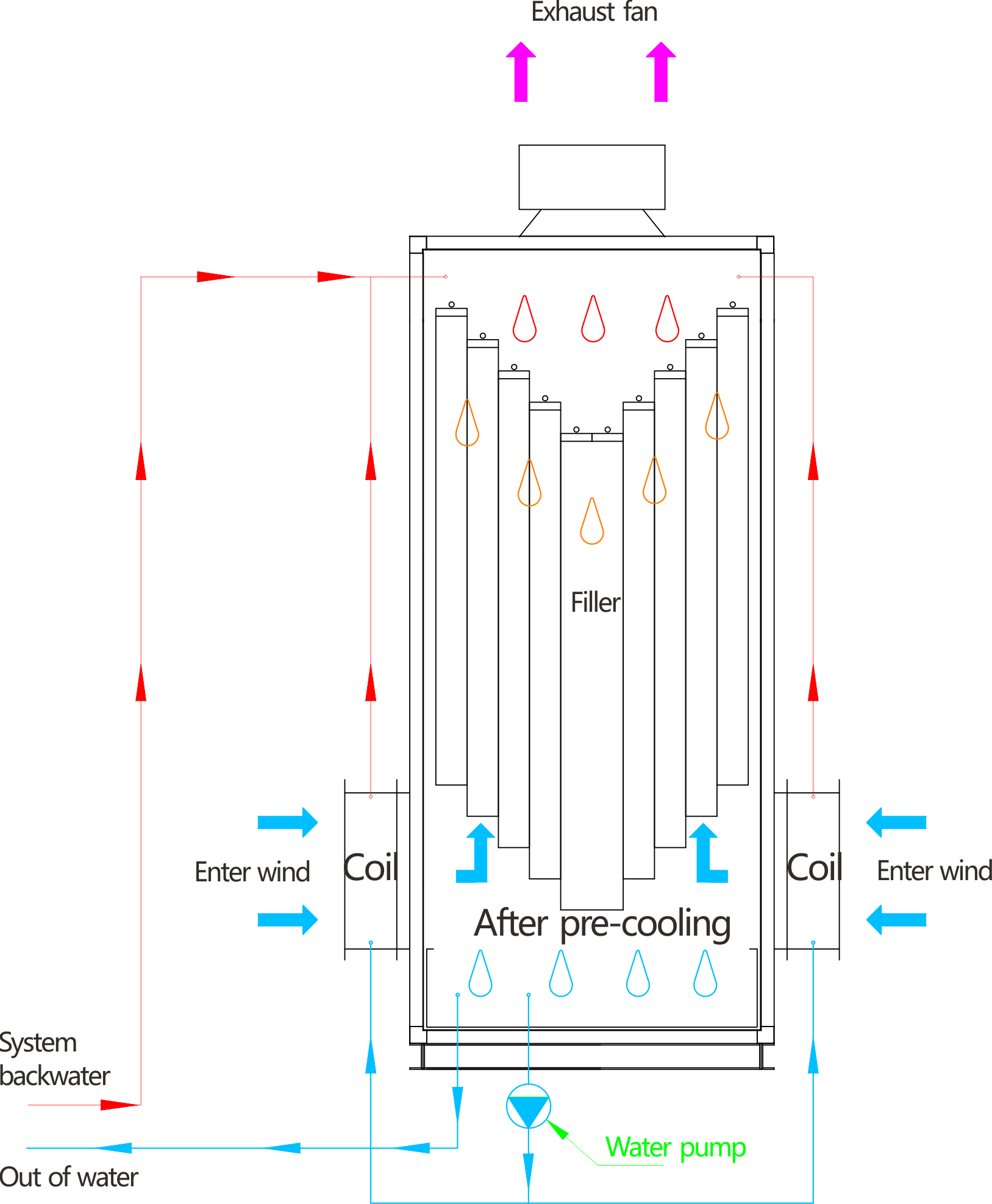

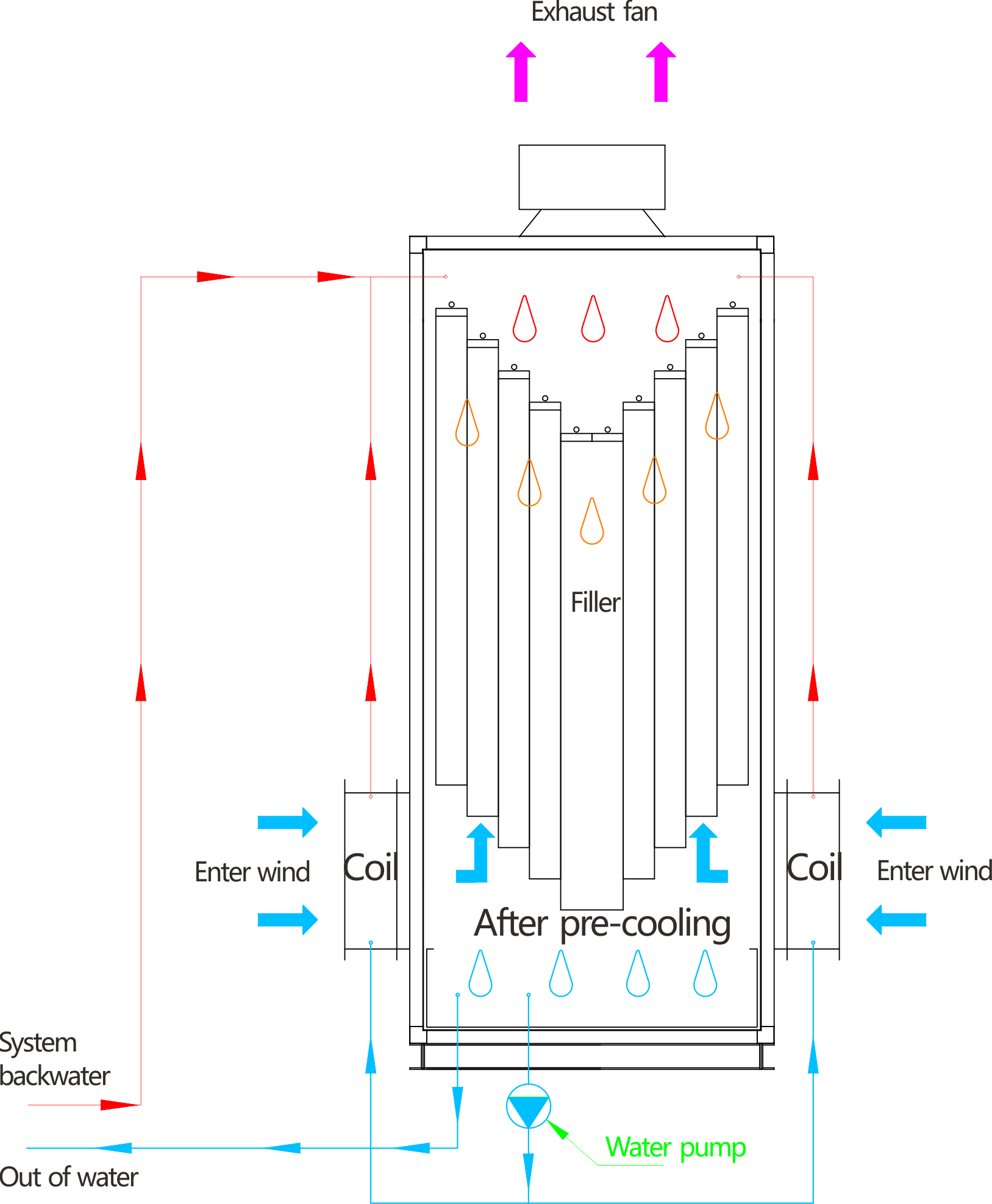

This product integrates a number of key technologies such as external cooling indirect evaporation, filler heat and moisture exchange, three-dimensional variable flow uniform water distribution, real-time water quality detection and processing, and intelligent group control. Features such as low noise, can replace mechanical refrigeration for applications such as fresh air treatment of public construction projects in dry areas, floor cold radiation cooling, etc., with obvious energy-saving effect, and it is also very suitable for energy-saving and cooling of large data centers.

Working Principle

Features

1. Compared with mechanical refrigeration equipment, it can save energy by more than 70% under the same cooling capacity and greatly reduce operating costs.

2. The filler is made of organic polymer material, which has good flame retardant and antibacterial properties.

3. The packing adopts a new structure design, which can be quickly disassembled and replaced, effectively reducing the maintenance cost in the later period.

4. It adopts DC brushless EC fan, which has the characteristics of high reliability, high efficiency, long life, low vibration, low noise and uninterrupted operation, and can effectively prevent the intrusion of rain, snow and sand, and keep the water quality clean.

5. The whole machine adopts PLC and touch screen intelligent control, providing a variety of interface types. Real-time detection of water temperature, automatic control of fan speed.

6. The water tank is made of stainless steel, which has good rust and corrosion resistance. There is a quick access port for the water tank, which is convenient for water tank cleaning and component maintenance.

7. The external cooling indirect evaporative pre-cooling coil adopts patented structure design to ensure clean drainage and prevent freezing and cracking in winter.

8. Large aperture three-dimensional water distribution technology, uniform water distribution, not easy to block; patented structure design, more suitable for variable flow operation.

9. The mechanical strength of the box body reaches European standards; the thermal insulation panel adopts new energy-saving materials that are safe and environmentally friendly.

10. The unit has complete protection functions, providing alarm functions such as power phase loss, undervoltage, antifreeze, and abnormal liquid level.

Application

Data centers, hospitals, schools, airports, high-speed rail, shopping malls, libraries, gymnasiums, exhibition halls, etc.

Optional Function (Non-Standard)

1. Intelligent group control function: group control, realize intelligent group control with 40 devices.

2. Water softening system: optional in hard areas, it can reduce the calcium ions in the site, reduce the maintenance workload, and effectively prolong the life of the labor force.

3. Combination plate replacement and one-time pumping system: realize fast on-site and reduce engineering quantity.

4. Combined mechanical refrigeration system: It proves that the cooling capacity of natural cold source is insufficient.

5. Circulating water descaling, filtration and fermentation devices: maintain the cleanliness of circulating water.

6. Antifreeze device: avoid the freezing of water in the water tank caused by the environment.

7. Lightning protection and surge protection device: lightning and equipment will not interfere with the impact of the power grid.

Specification

| Model | AGS40 (Single module) | AGS50 (Single module) | AGS80 (Single module) | AGS100 (Single module) | AGS150 (Single module) | AGS200 (Single module) |

| Maximum Circulating Water Volume (m³/h) | 40 | 50 | 80 | 100 | 150 | 200 |

| Supply and Return Water Temperature Difference (℃) | 3/5/10 | 3/5/10 | 3/5/10 | 3/5/10 | 3/5/10 | 3/5/10 |

| Max Power (kW) | 10 | 12 | 18 | 25 | 35 | 50 |

| Max Noise (dB(A)) | 72 | 73 | 76 | 78 | 80 | 83 |

For specific performance parameters, dimensions and use of non-standard working conditions, please contact the company's technical department.

Project Cases

![]() Gymnasium Canteen Application Case

Gymnasium Canteen Application Case

![]() Data Room Ventilation and Cooling

Data Room Ventilation and Cooling

Overview

This product integrates a number of key technologies such as external cooling indirect evaporation, filler heat and moisture exchange, three-dimensional variable flow uniform water distribution, real-time water quality detection and processing, and intelligent group control. Features such as low noise, can replace mechanical refrigeration for applications such as fresh air treatment of public construction projects in dry areas, floor cold radiation cooling, etc., with obvious energy-saving effect, and it is also very suitable for energy-saving and cooling of large data centers.

Working Principle

Features

1. Compared with mechanical refrigeration equipment, it can save energy by more than 70% under the same cooling capacity and greatly reduce operating costs.

2. The filler is made of organic polymer material, which has good flame retardant and antibacterial properties.

3. The packing adopts a new structure design, which can be quickly disassembled and replaced, effectively reducing the maintenance cost in the later period.

4. It adopts DC brushless EC fan, which has the characteristics of high reliability, high efficiency, long life, low vibration, low noise and uninterrupted operation, and can effectively prevent the intrusion of rain, snow and sand, and keep the water quality clean.

5. The whole machine adopts PLC and touch screen intelligent control, providing a variety of interface types. Real-time detection of water temperature, automatic control of fan speed.

6. The water tank is made of stainless steel, which has good rust and corrosion resistance. There is a quick access port for the water tank, which is convenient for water tank cleaning and component maintenance.

7. The external cooling indirect evaporative pre-cooling coil adopts patented structure design to ensure clean drainage and prevent freezing and cracking in winter.

8. Large aperture three-dimensional water distribution technology, uniform water distribution, not easy to block; patented structure design, more suitable for variable flow operation.

9. The mechanical strength of the box body reaches European standards; the thermal insulation panel adopts new energy-saving materials that are safe and environmentally friendly.

10. The unit has complete protection functions, providing alarm functions such as power phase loss, undervoltage, antifreeze, and abnormal liquid level.

Application

Data centers, hospitals, schools, airports, high-speed rail, shopping malls, libraries, gymnasiums, exhibition halls, etc.

Optional Function (Non-Standard)

1. Intelligent group control function: group control, realize intelligent group control with 40 devices.

2. Water softening system: optional in hard areas, it can reduce the calcium ions in the site, reduce the maintenance workload, and effectively prolong the life of the labor force.

3. Combination plate replacement and one-time pumping system: realize fast on-site and reduce engineering quantity.

4. Combined mechanical refrigeration system: It proves that the cooling capacity of natural cold source is insufficient.

5. Circulating water descaling, filtration and fermentation devices: maintain the cleanliness of circulating water.

6. Antifreeze device: avoid the freezing of water in the water tank caused by the environment.

7. Lightning protection and surge protection device: lightning and equipment will not interfere with the impact of the power grid.

Specification

| Model | AGS40 (Single module) | AGS50 (Single module) | AGS80 (Single module) | AGS100 (Single module) | AGS150 (Single module) | AGS200 (Single module) |

| Maximum Circulating Water Volume (m³/h) | 40 | 50 | 80 | 100 | 150 | 200 |

| Supply and Return Water Temperature Difference (℃) | 3/5/10 | 3/5/10 | 3/5/10 | 3/5/10 | 3/5/10 | 3/5/10 |

| Max Power (kW) | 10 | 12 | 18 | 25 | 35 | 50 |

| Max Noise (dB(A)) | 72 | 73 | 76 | 78 | 80 | 83 |

For specific performance parameters, dimensions and use of non-standard working conditions, please contact the company's technical department.

Project Cases

![]() Gymnasium Canteen Application Case

Gymnasium Canteen Application Case

![]() Data Room Ventilation and Cooling

Data Room Ventilation and Cooling