Your current location:Home > Products > Evaporative Cooling Media

Overview

The fire-resistant and flame-retardant wet curtain produced by Aolan Company is made of imported polymer materials through special processing, does not contain glass fiber, and has the characteristics of high wet stiffness, high evaporation efficiency, low resistance and environmental protection. The core supporting components of evaporation equipment are widely used, especially in the wet film humidifier in the data room, the cooling of power plant equipment and the cooling of subway fresh air and other equipment or fields.

Features

1. Special polymer material, high water absorption, high chemical stability, acid and alkali resistance, strong weather resistance, never rot.

2. Permanent B1 flame retardant, water absorption efficiency up to 250%, evaporation efficiency up to 95%.

3. The use of environmentally friendly glue, no odor, no phenol and other harmful substances to the human body.

4. The main materials and auxiliary materials used are all environmentally friendly materials, which meet the requirements of environmental protection ROHS and REACH certification

5. Each process is carefully manufactured, and quality inspection is strictly implemented to ensure quality.

6. Patented high-precision cutting equipment, small tolerance, no burr, beautiful appearance.

7. Patented formula, antibacterial and mildew proof authoritative certification.

Application

It is used in communication equipment rooms, data centers, and special industrial fields as the core components of humidification and flame retardant.

Specification

| Model | 5070 (Single Module) | 5090 (Single Module) | 7090 (Single Module) |

| Maximum Humidifying Capacity (kg/h) | ≤160 | ≤160 | ≤160 |

| Highest Efficiency | ≤95% | ≤95% | ≤95% |

| Max Width (mm) | ≤1000 | ≤1000 | ≤1000 |

| Max Height (mm) | ≤1000 | ≤1000 | ≤1000 |

| Max Thickness (mm) | ≤300 | ≤300 | ≤300 |

For specific performance parameters, dimensions and non-standard customization, please contact the company's technical department.

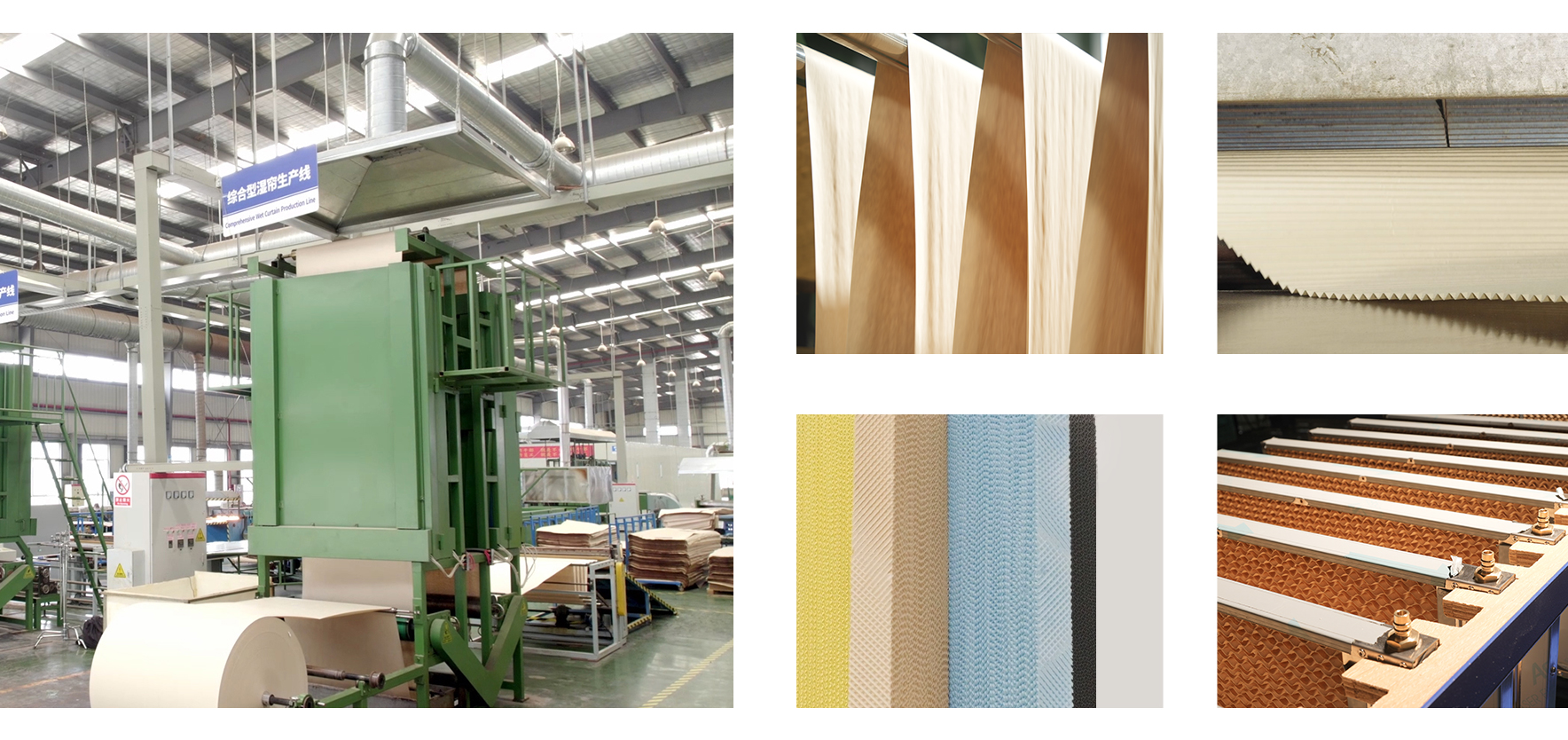

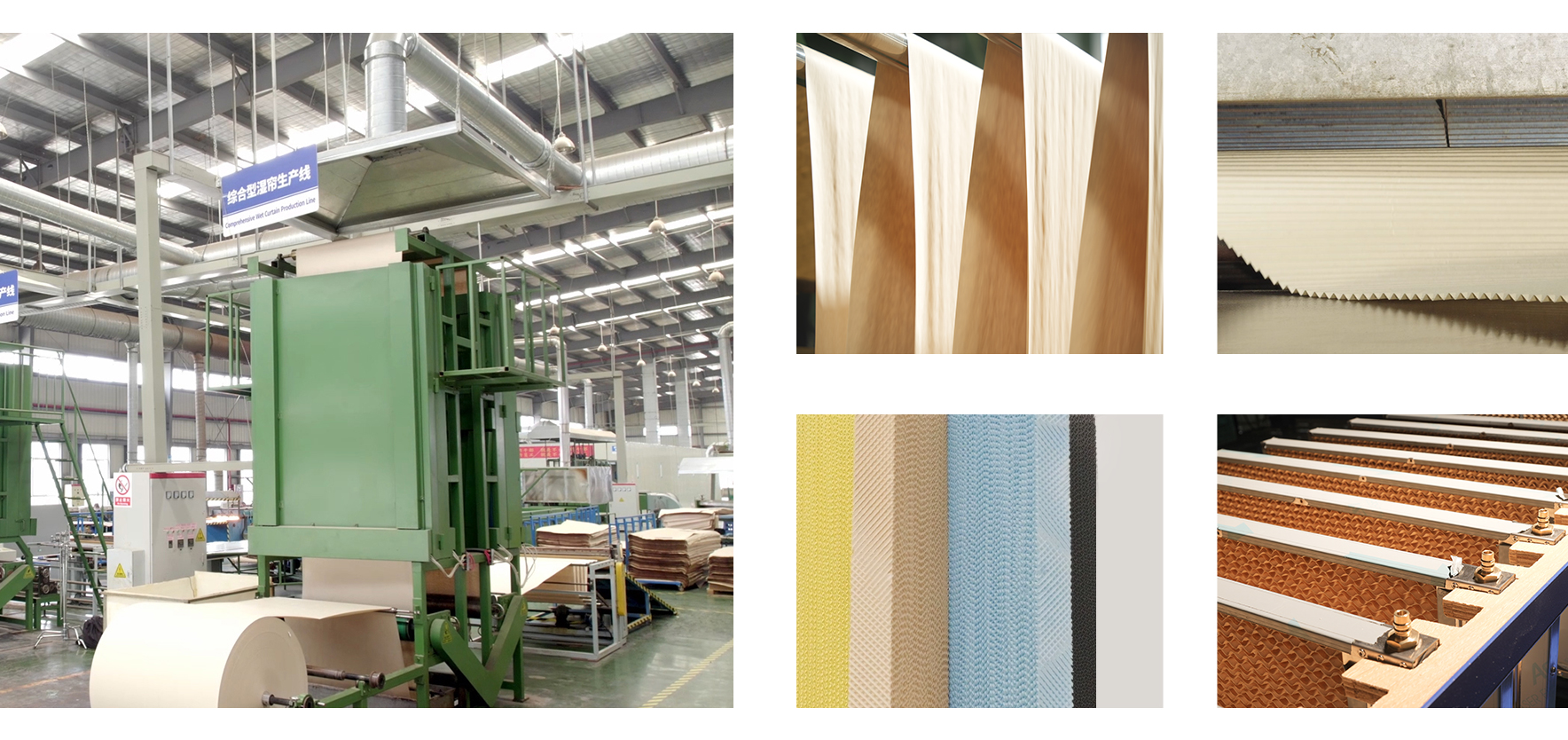

List Of Production

Overview

The fire-resistant and flame-retardant wet curtain produced by Aolan Company is made of imported polymer materials through special processing, does not contain glass fiber, and has the characteristics of high wet stiffness, high evaporation efficiency, low resistance and environmental protection. The core supporting components of evaporation equipment are widely used, especially in the wet film humidifier in the data room, the cooling of power plant equipment and the cooling of subway fresh air and other equipment or fields.

Features

1. Special polymer material, high water absorption, high chemical stability, acid and alkali resistance, strong weather resistance, never rot.

2. Permanent B1 flame retardant, water absorption efficiency up to 250%, evaporation efficiency up to 95%.

3. The use of environmentally friendly glue, no odor, no phenol and other harmful substances to the human body.

4. The main materials and auxiliary materials used are all environmentally friendly materials, which meet the requirements of environmental protection ROHS and REACH certification

5. Each process is carefully manufactured, and quality inspection is strictly implemented to ensure quality.

6. Patented high-precision cutting equipment, small tolerance, no burr, beautiful appearance.

7. Patented formula, antibacterial and mildew proof authoritative certification.

Application

It is used in communication equipment rooms, data centers, and special industrial fields as the core components of humidification and flame retardant.

Specification

| Model | 5070 (Single Module) | 5090 (Single Module) | 7090 (Single Module) |

| Maximum Humidifying Capacity (kg/h) | ≤160 | ≤160 | ≤160 |

| Highest Efficiency | ≤95% | ≤95% | ≤95% |

| Max Width (mm) | ≤1000 | ≤1000 | ≤1000 |

| Max Height (mm) | ≤1000 | ≤1000 | ≤1000 |

| Max Thickness (mm) | ≤300 | ≤300 | ≤300 |

For specific performance parameters, dimensions and non-standard customization, please contact the company's technical department.

List Of Production